Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

With the acceleration of urbanization and the continuous growth of population, the problem of waste disposal has become increasingly prominent. Waste incineration has been widely used as an efficient and reduced waste disposal method. As one of the core components of the incinerator, the high-temperature resistant waste incinerator grate castings play a vital role in improving the incineration efficiency and ensuring the stable operation of the equipment.

1. Advantages of high-temperature resistant waste incinerator grate castings

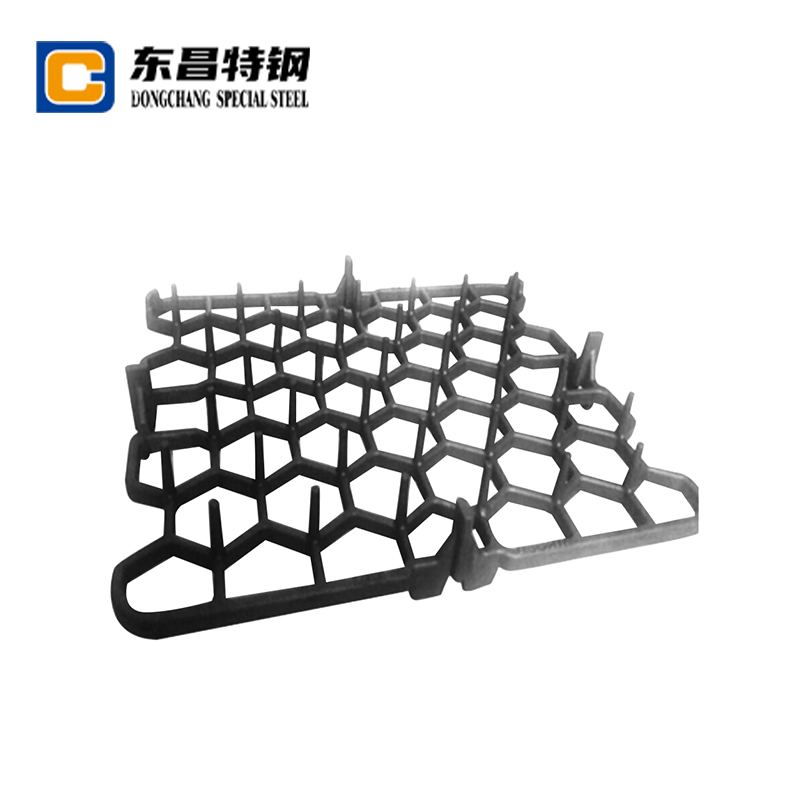

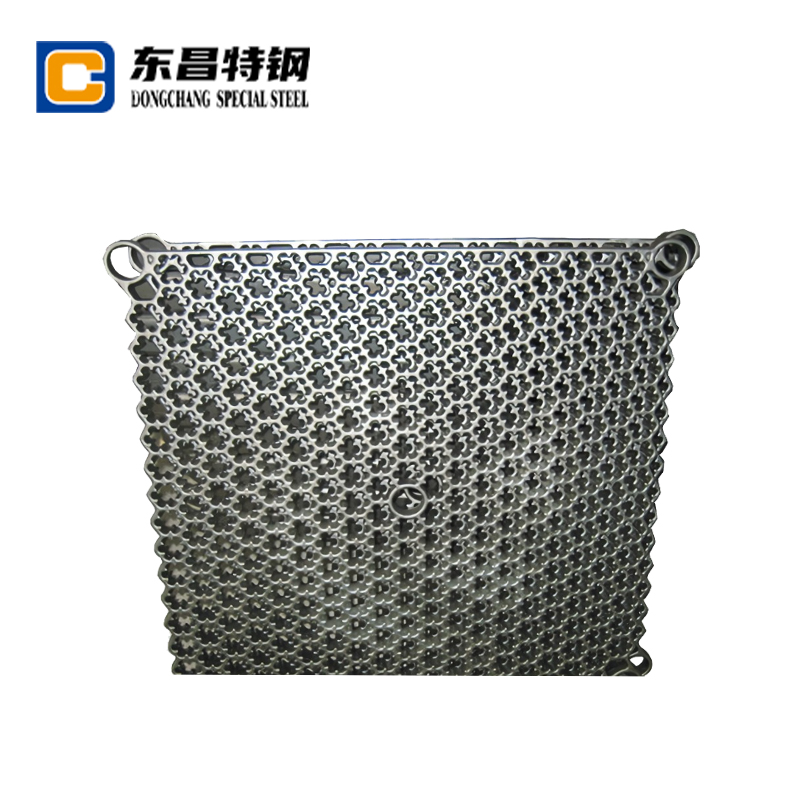

Efficient combustion: The high-temperature resistant grate is made of high-quality heat-resistant materials and can withstand long-term operation in high-temperature environments to ensure that the garbage is fully burned during the incineration process. This not only improves the incineration efficiency, but also reduces the generation of unburned materials and reduces environmental pollution.

Strong stability: The grate has a reasonable structural design that can evenly distribute the garbage and avoid local overheating or uneven combustion. At the same time, its high-temperature resistance ensures that it is not easy to deform or damage at high temperatures, thereby extending the service life of the incinerator.

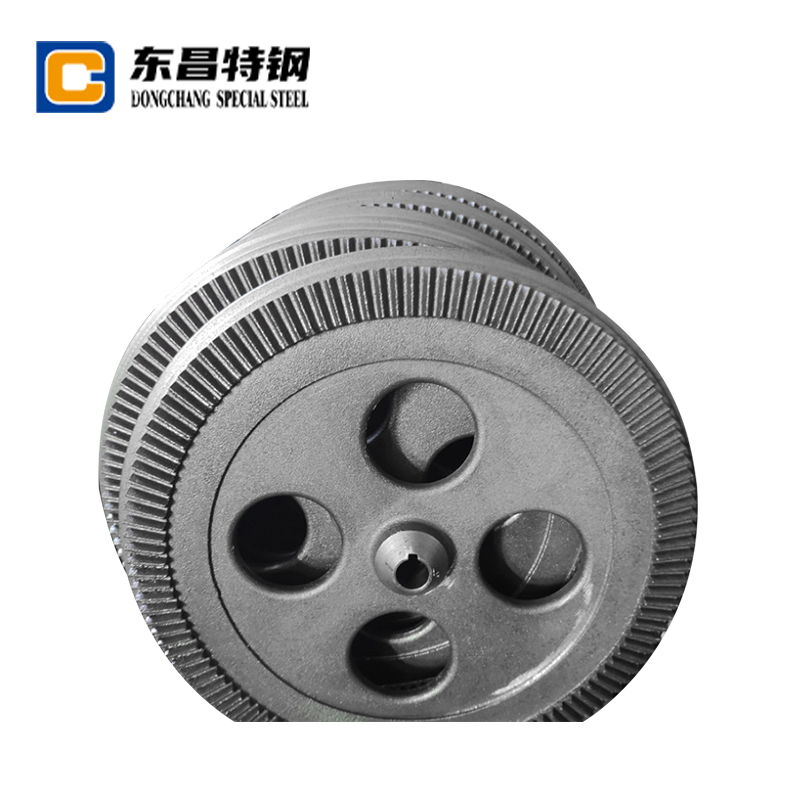

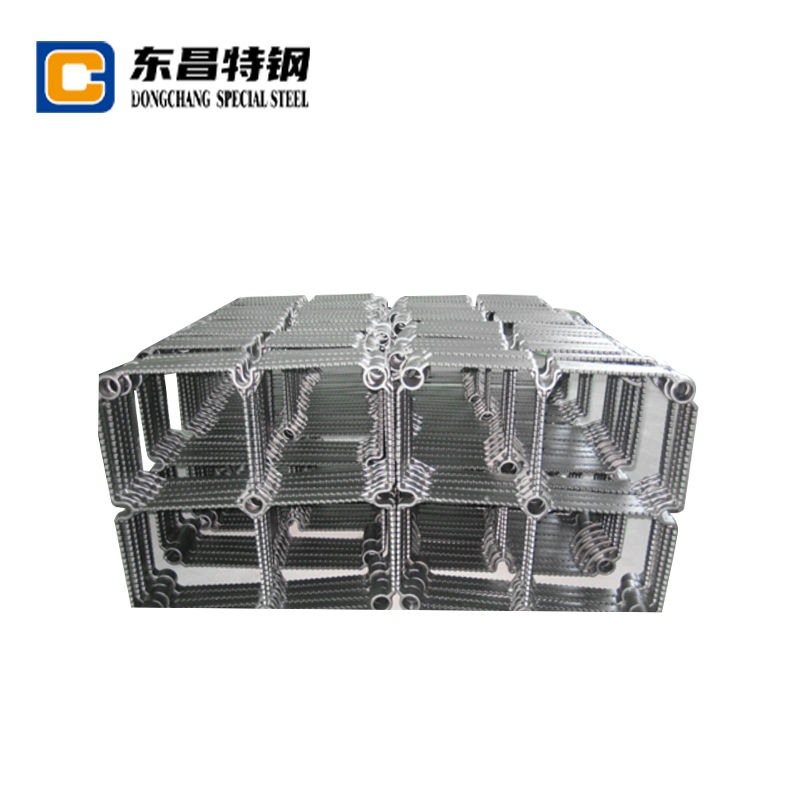

Easy maintenance: The high-temperature resistant grate is usually modularly designed for easy disassembly and replacement. When the grate is worn or damaged, it can be quickly replaced, reducing the impact on the overall operation of the incinerator.

Environmental protection and energy saving: By improving the incineration efficiency, the high-temperature resistant grate helps to reduce the emission of harmful gases and reduce pollution to the environment. At the same time, fully burned garbage can generate more heat energy for power generation or heating, realizing energy recycling.

2. Application of high-temperature resistant garbage incinerator grate castings in the industry

In the garbage incineration industry, high-temperature resistant grates have become an indispensable key component. With the improvement of environmental awareness and the continuous advancement of technology, more and more garbage incineration plants have begun to adopt advanced high-temperature resistant grate technology to improve incineration efficiency and environmental performance. These grates are not only suitable for the incineration of urban domestic waste, but also for the incineration of special waste such as medical waste and industrial waste.

3. Key technologies to improve incineration efficiency

Optimize grate design: By improving the structure and materials of the grate, improve its adaptability to garbage and combustion efficiency. For example, adopt more advanced combustion control systems and high-efficiency burners to ensure full and stable combustion.

Precisely control combustion parameters: By real-time monitoring and adjusting combustion parameters such as furnace temperature and oxygen volume, the incineration process can be optimized. This helps reduce carbon emissions and harmful substances generated by incomplete combustion.

Strengthen waste gas treatment: Equipped with professional waste gas treatment equipment to deeply purify the waste gas generated by incineration, effectively reduce the content of harmful substances in the waste gas, and meet environmental emission standards.

Residual heat recovery: Use the waste heat generated during the incineration process for power generation or heating, etc., to improve energy utilization and reduce energy consumption.

As one of the key technologies to improve incineration efficiency, high-temperature resistant waste incinerator grate castings play an important role in the waste incineration industry. By continuously optimizing grate design, accurately controlling combustion parameters, strengthening waste gas treatment and waste heat recovery, etc., the incineration efficiency and environmental performance can be further improved, providing a more efficient and environmentally friendly solution for urban waste treatment.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878