Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

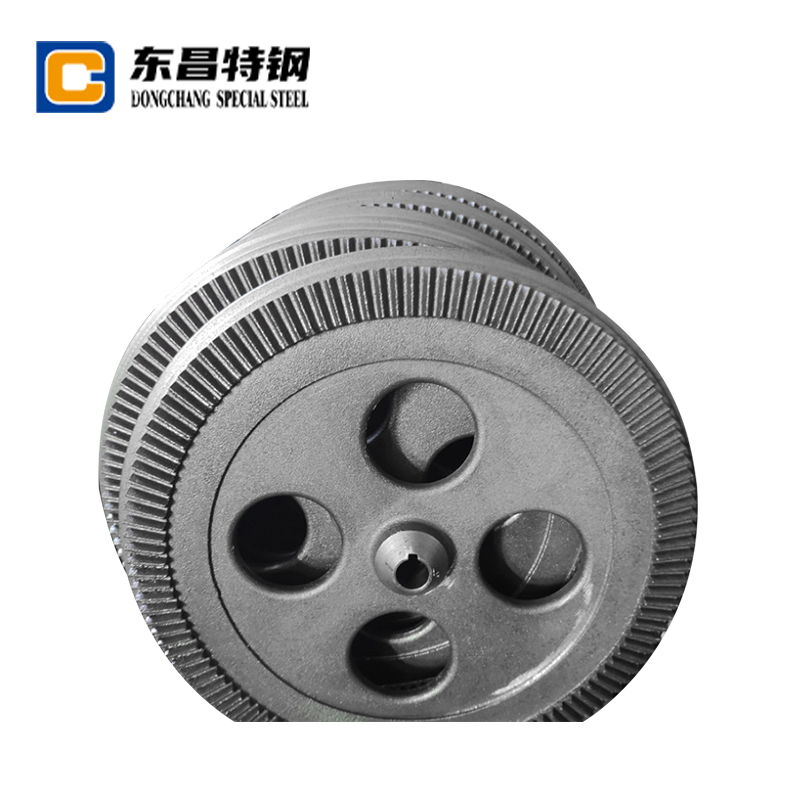

Top manufacturers opt for custom gas furnace roller castings in their heat treatment processes due to several key advantages that enhance efficiency, durability, and product quality. Here's a detailed breakdown:

1. Tailored Design for Optimal Performance

Custom Fit: Manufacturers can design roller castings to match the specific dimensions and load requirements of their gas furnaces. This ensures seamless integration and reduces stress on components.

Material Selection: Custom castings allow the use of high-performance alloys (e.g., heat-resistant steels, nickel-based alloys) tailored to withstand extreme temperatures and corrosive environments, extending service life.

2. Enhanced Durability and Longevity

Wear Resistance: Custom designs often incorporate hardened surfaces or coatings (e.g., ceramic, carbide) to resist abrasion and thermal fatigue, reducing maintenance frequency.

Thermal Stability: Precision casting techniques minimize internal stresses, preventing warping or cracking under cyclic heating and cooling.

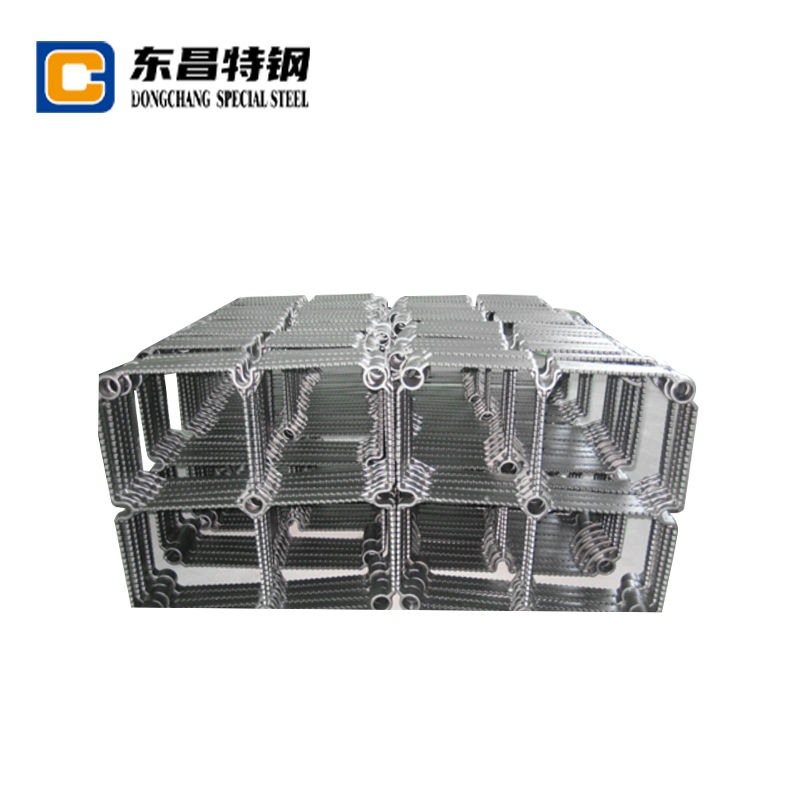

3. Improved Heat Treatment Efficiency

Uniform Heat Distribution: Carefully engineered roller profiles ensure even material movement through the furnace, minimizing temperature gradients and achieving consistent heat treatment results.

Reduced Energy Consumption: Smooth roller surfaces and optimized spacing lower friction, decreasing the energy required to drive the furnace conveyor system.

4. Cost-Effectiveness Over Time

Lower Downtime: Durable custom castings reduce breakdowns, minimizing production interruptions and associated costs.

Extended Lifespan: High-quality materials and design often outlast off-the-shelf options, reducing replacement frequency and total cost of ownership.

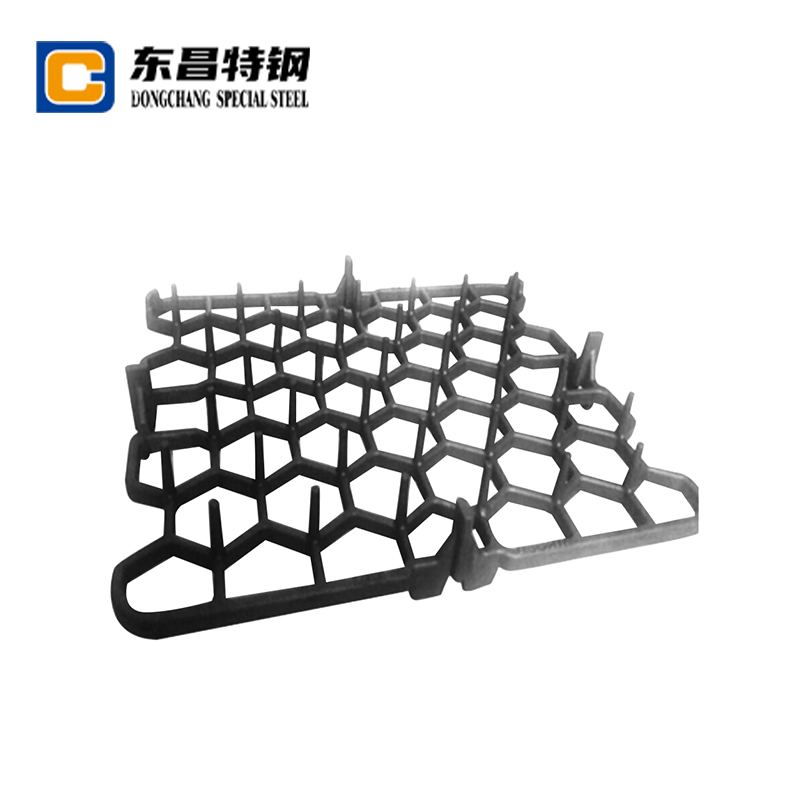

5. Compliance with Industry Standards

Precision Engineering: Custom castings meet stringent tolerances (e.g., ISO, ASTM standards), ensuring compatibility with automated systems and quality control requirements.

Safety Features: Designs can incorporate safety mechanisms (e.g., anti-slip surfaces, load-bearing reinforcements) to protect operators and equipment.

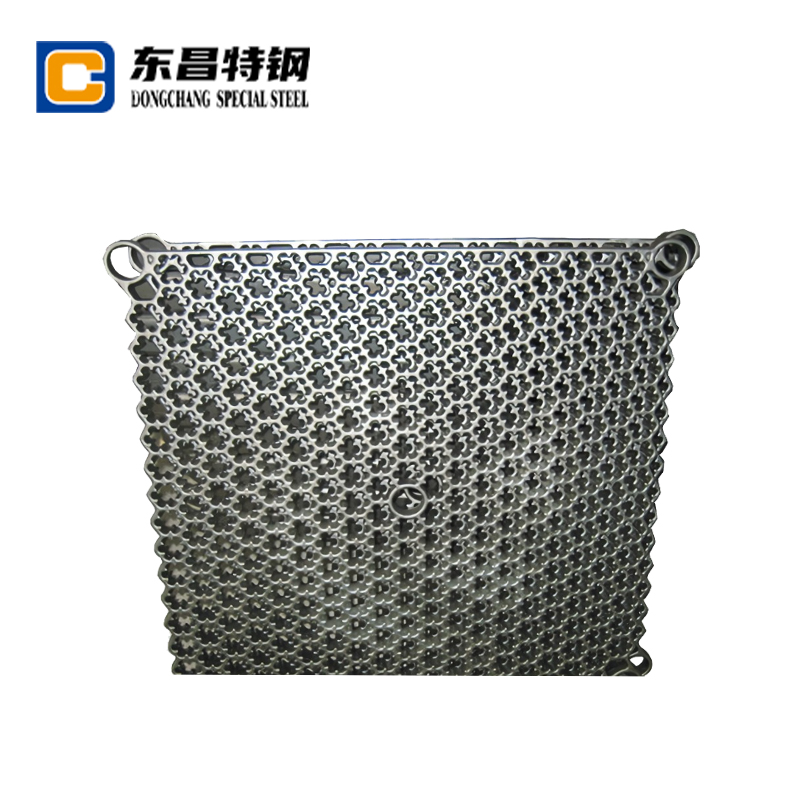

6. Scalability and Adaptability

Flexibility: Manufacturers can adjust casting designs to accommodate upgrades in furnace capacity or process changes (e.g., new material types, higher temperatures).

Modular Systems: Custom rollers can be part of a scalable solution, allowing incremental expansions without overhauling the entire furnace.

7. Competitive Advantage

Differentiation: Superior heat treatment consistency improves product quality, giving manufacturers an edge in markets where precision and reliability are critical (e.g., aerospace, automotive).

Innovation: Collaborating with casting experts fosters innovation in process optimization and material science.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878