Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

Understanding Alloy Steel Material Tray Castings and Their Industrial Significance

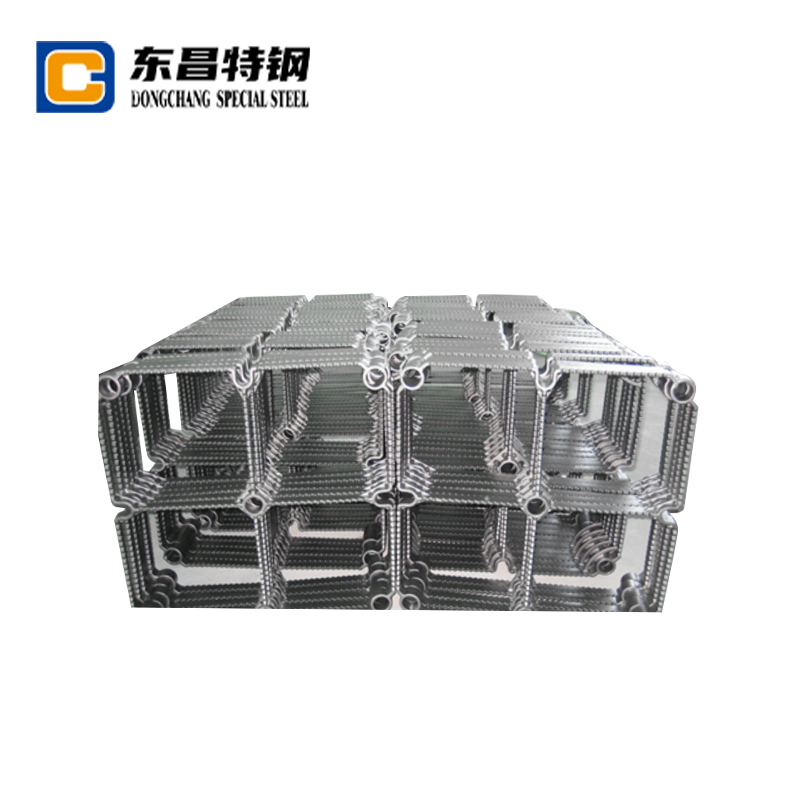

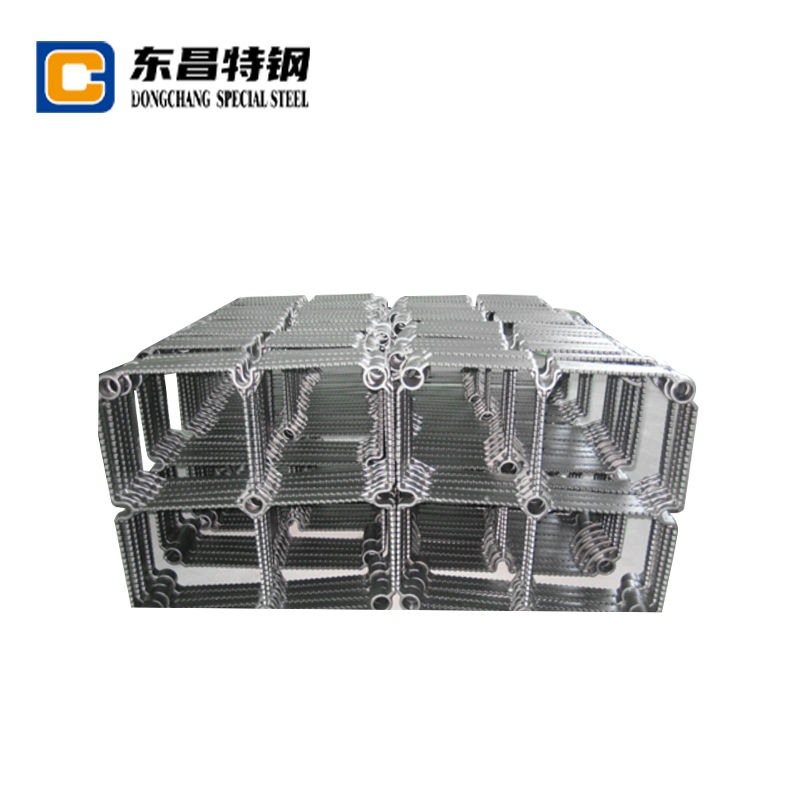

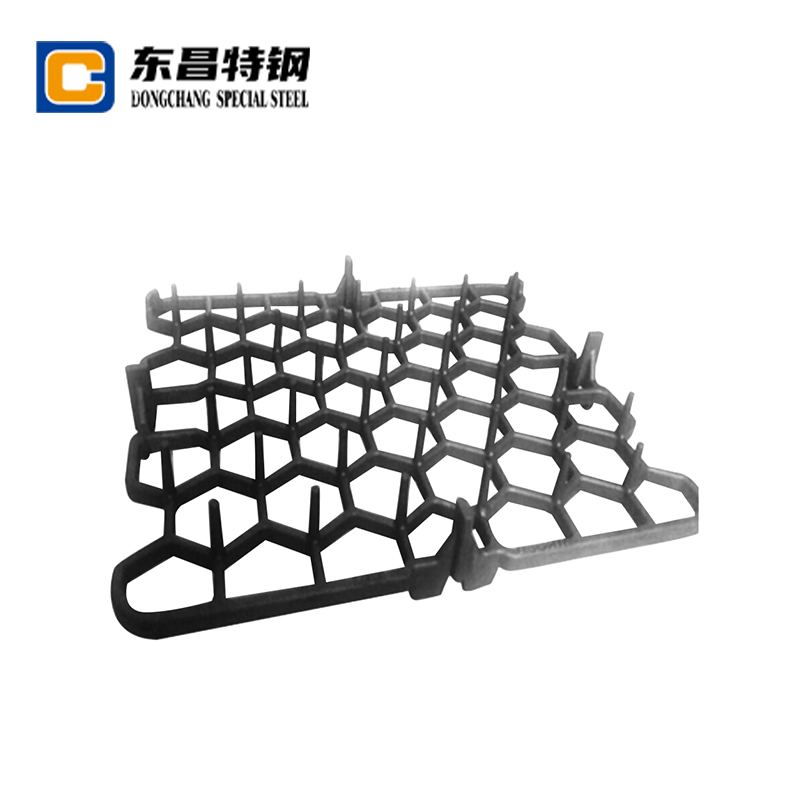

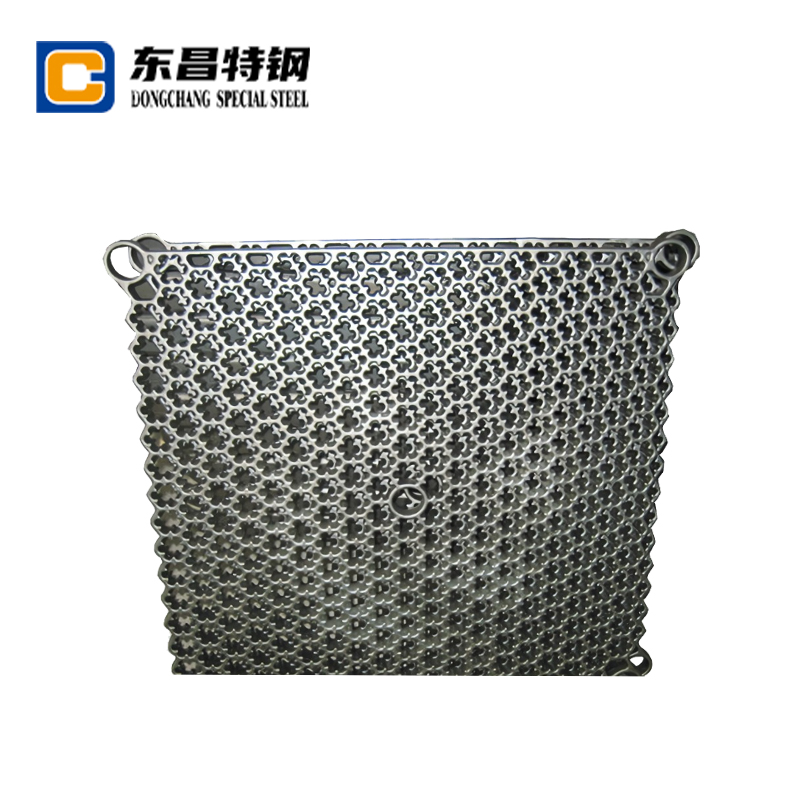

Alloy steel tray castings are critical components in heavy-duty industrial applications, offering superior strength, durability, and resistance to extreme conditions. These castings are engineered to withstand high stress, corrosion, and wear, making them indispensable in sectors like mining, construction, and manufacturing. The unique composition of alloy steel—typically incorporating elements like chromium, nickel, and molybdenum—enhances its mechanical properties beyond standard carbon steel.

Key Characteristics of Alloy Steel Tray Castings

Alloy steel tray castings stand out due to their exceptional properties:

- High Tensile Strength: Capable of bearing heavy loads without deformation.

- Wear Resistance: Ideal for abrasive environments due to hardened surfaces.

- Corrosion Resistance: Performs well in moist or chemically aggressive settings.

- Thermal Stability: Maintains structural integrity under high temperatures.

Compared to standard steel, alloy steel tray castings offer 20-30% greater fatigue life, as demonstrated in industrial stress tests. Below is a comparison of key metrics:

| Property | Alloy Steel Tray Castings | Standard Carbon Steel |

|---|---|---|

| Yield Strength | 550-850 MPa | 250-400 MPa |

| Impact Resistance | High (50-100 J at -40°C) | Moderate (20-40 J at -40°C) |

Benefits of Using Custom Alloy Steel Trays in Heavy Machinery

Custom alloy steel trays provide tailored solutions for specialized equipment, ensuring optimal performance in demanding operations. Their adaptability allows for precise dimensional configurations, weight distribution, and load-bearing capacities.

Applications in Critical Industries

These trays are widely used in:

- Mining: Conveyor systems and ore processing equipment.

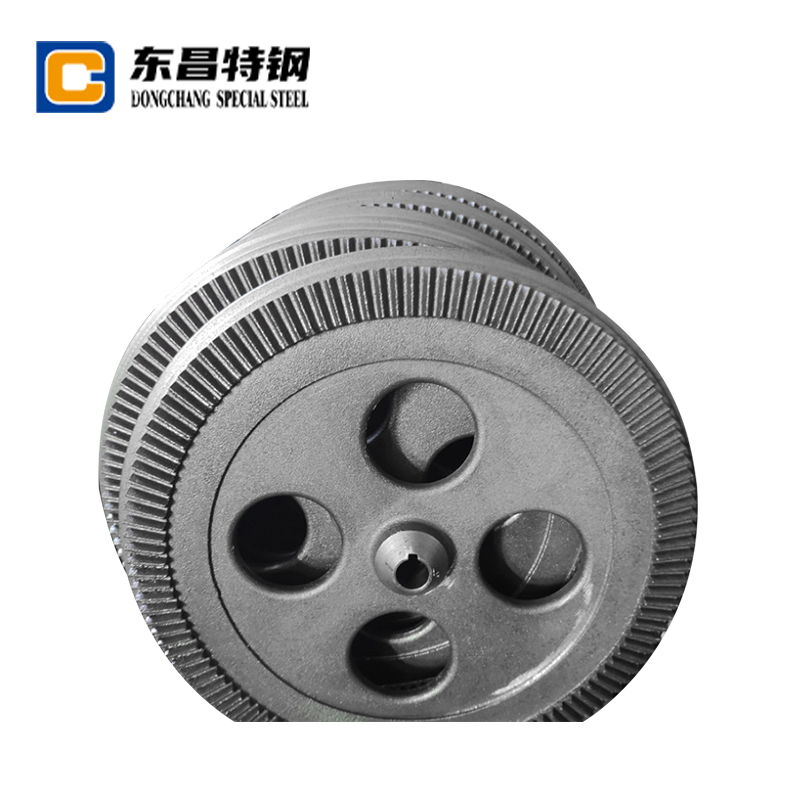

- Energy: Turbine components and power transmission parts.

- Transportation: Heavy vehicle undercarriages and cargo supports.

A case study in mining operations showed that custom alloy steel trays reduced maintenance downtime by 45% compared to generic alternatives.

Heat Treatment Processes for Enhanced Alloy Steel Tray Durability

Heat treatment is pivotal in maximizing the performance of alloy steel tray castings. Processes like quenching, tempering, and annealing alter the microstructure to achieve desired hardness and toughness.

Common Heat Treatment Techniques

Below are the most effective methods:

- Quenching: Rapid cooling to increase hardness.

- Tempering: Reheating to reduce brittleness.

- Case Hardening: Surface enhancement for wear resistance.

Data shows that properly heat-treated alloy steel trays exhibit 60% longer service life in abrasive environments.

Comparing Alloy Steel vs. Stainless Steel Tray Castings for Industrial Use

While both materials are robust, their suitability depends on specific operational requirements. Alloy steel excels in high-stress applications, whereas stainless steel offers superior corrosion resistance.

Performance Comparison

| Criteria | Alloy Steel Tray Castings | Stainless Steel Tray Castings |

|---|---|---|

| Cost Efficiency | Higher (due to specialized alloys) | Lower (for standard grades) |

| Maintenance Frequency | Moderate (requires coatings) | Low (inherently corrosion-resistant) |

For industries prioritizing load capacity over corrosion resistance, alloy steel material tray castings are the clear choice.

How to Select the Right Alloy Steel Grade for Tray Casting Applications

Choosing the appropriate alloy steel grade involves evaluating operational stressors, environmental conditions, and budget constraints.

Key Selection Criteria

- Mechanical Loads: Higher grades (e.g., 4140) for dynamic stresses.

- Temperature Extremes: Chromium-molybdenum alloys for thermal stability.

- Corrosion Exposure: Weather-resistant steels for outdoor use.

Engineers recommend consulting ASTM or ISO standards when specifying alloy steel trays for high-temperature environments to ensure compliance.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878