Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

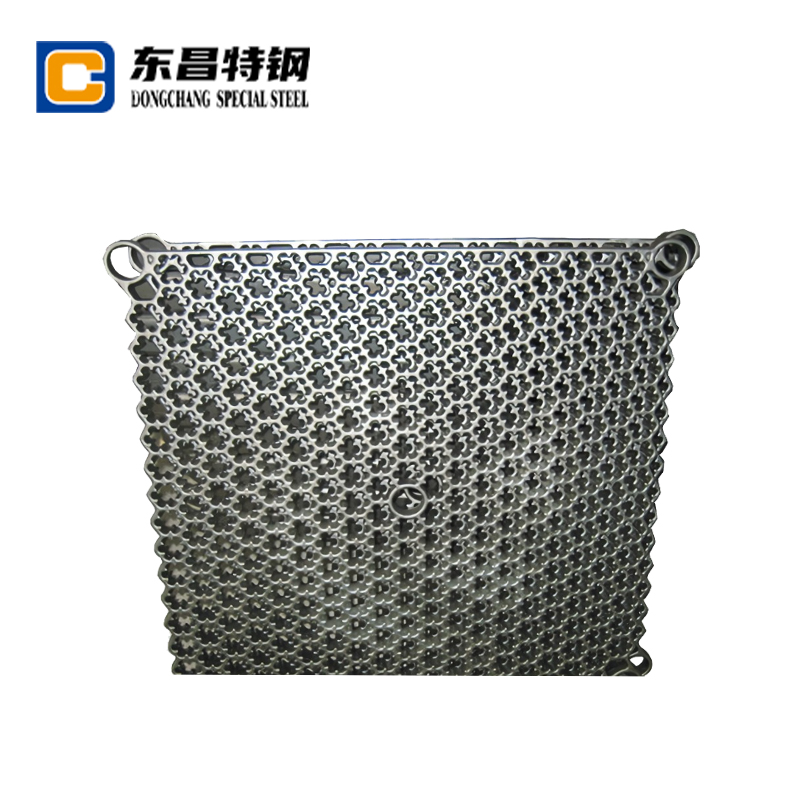

Understanding Heat Resistant Steel Frame Castings

Heat resistant steel material frame castings are specialized components designed to withstand extreme temperatures while maintaining structural integrity. These castings play a crucial role in industries where high-temperature operations are routine, offering superior performance compared to standard steel alloys. The best heat resistant steel alloys for industrial castings combine exceptional thermal stability with mechanical strength, making them indispensable for demanding applications.

Heat Resistant and High-Temperature Resistant Material Frame Castings

Key Characteristics of Heat Resistant Steel Castings

These specialized materials exhibit several distinctive properties that set them apart from conventional steel:

- Excellent oxidation resistance at elevated temperatures

- High creep resistance under sustained loads

- Good thermal fatigue properties

- Retention of mechanical strength at high temperatures

- Resistance to scaling and corrosion in hot environments

Microstructural Advantages

The superior performance of heat resistant steel castings stems from their carefully engineered microstructure. Alloying elements like chromium, nickel, and molybdenum form stable carbides and intermetallic phases that prevent degradation at high temperatures. This microstructural stability is what makes them the top choice for high temperature frame components in critical applications.

Applications of Heat Resistant Steel Frame Castings

The unique properties of these materials make them suitable for numerous industrial applications where temperature extremes are encountered. Their use spans across multiple sectors, from energy production to manufacturing processes.

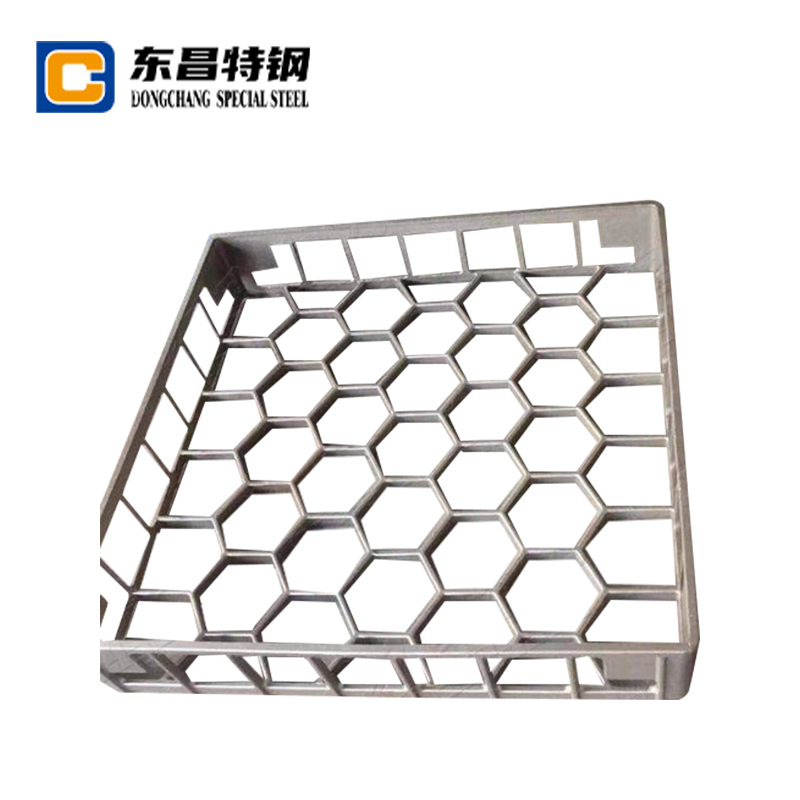

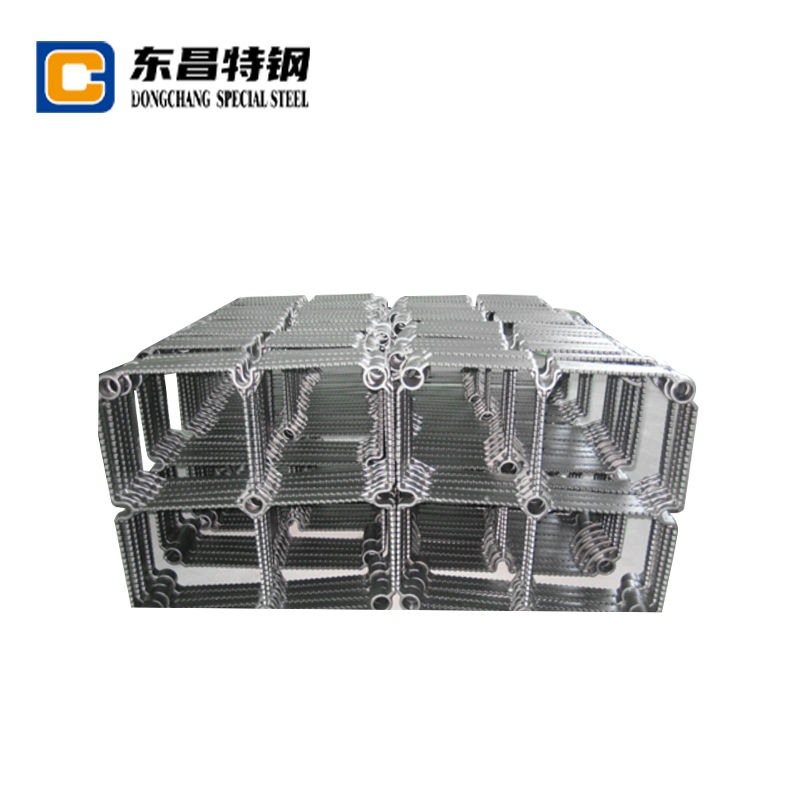

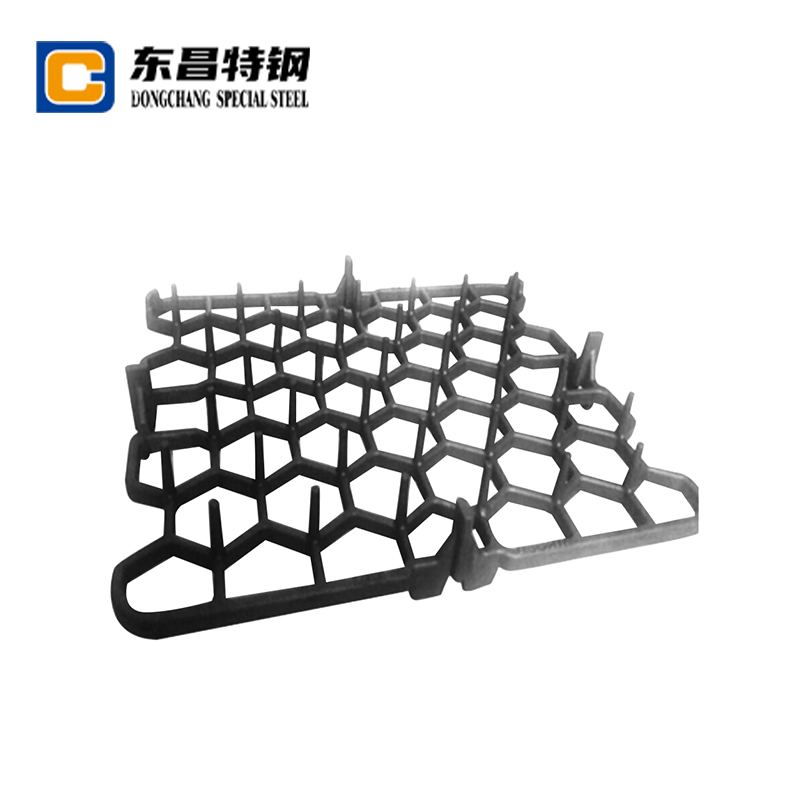

Industrial Furnace Components

Heat resistant steel castings form the structural framework of industrial furnaces, withstanding continuous exposure to temperatures exceeding 1000°C. These components include:

- Furnace doors and frames

- Heat treatment baskets

- Roller hearth systems

- Burner nozzles and supports

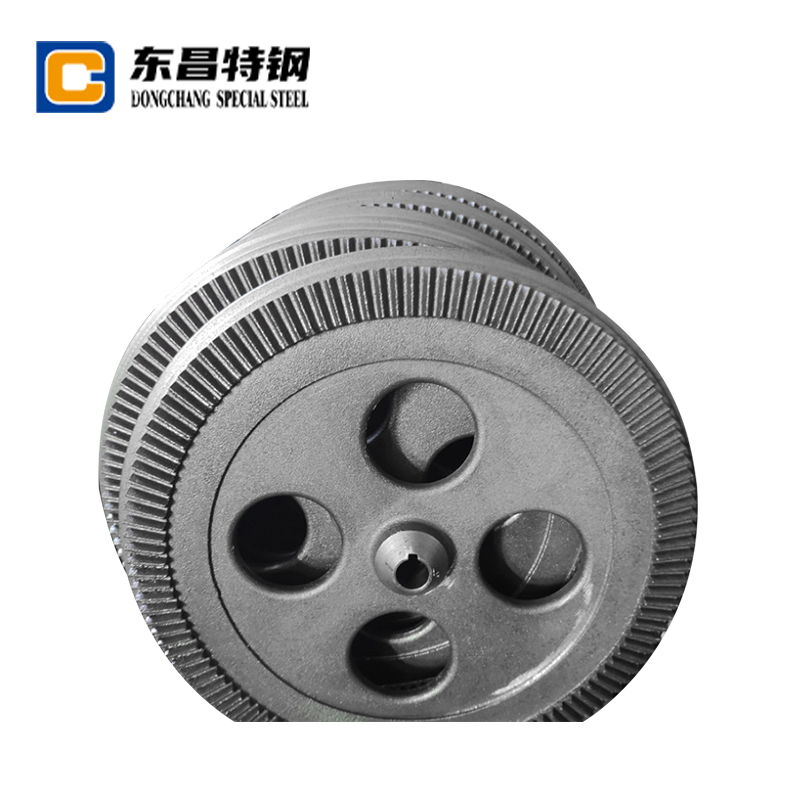

Power Generation Equipment

In power plants, durable heat resistant casting solutions are essential for components like turbine housings, boiler supports, and exhaust systems. These parts must endure both high temperatures and mechanical stresses throughout their service life.

Comparing Heat Resistant Steel Grades for Frame Castings

Different grades of heat resistant steel offer varying performance characteristics. Understanding these differences is crucial when selecting cost-effective heat resistant frame materials for specific applications.

Common Heat Resistant Steel Grades

| Grade | Maximum Service Temperature | Key Alloying Elements | Primary Applications |

|---|---|---|---|

| HK30 | 1100°C | 25Cr-20Ni | Furnace parts, radiant tubes |

| HP40 | 1150°C | 25Cr-35Ni-Nb | Petrochemical furnace components |

| 310 | 1050°C | 25Cr-20Ni | Heat treatment equipment |

Selection Criteria

When choosing between different grades, consider these factors:

- Operating temperature range

- Cyclic vs. continuous heating

- Mechanical load requirements

- Atmosphere (oxidizing, reducing, etc.)

- Thermal shock potential

Manufacturing Process for Heat Resistant Steel Castings

The production of high-quality heat resistant steel frame castings requires specialized foundry techniques to ensure optimal properties in the final product.

Casting Methods

Several casting methods are employed depending on the component size and complexity:

- Sand casting for large, complex shapes

- Investment casting for precision components

- Centrifugal casting for cylindrical parts

Heat Treatment Considerations

Post-casting heat treatments are critical for achieving the desired microstructure and properties. These may include:

- Solution annealing to dissolve carbides

- Stabilization treatments to prevent sensitization

- Stress relieving to minimize residual stresses

Maintenance and Lifespan Extension Strategies

Proper maintenance can significantly extend the service life of long-lasting heat resistant steel frames, reducing replacement costs and downtime.

Inspection Techniques

Regular inspections help identify potential issues before they lead to failure:

- Visual examination for cracks and distortion

- Ultrasonic testing for internal defects

- Dimensional checks for creep deformation

Repair Methods

When damage occurs, several repair options exist:

- Welding with matching filler metals

- Metal stitching for crack repair

- Protective coatings to restore surface integrity

Future Trends in Heat Resistant Steel Castings

The development of new alloys and manufacturing techniques continues to push the boundaries of what's possible with heat resistant steel frame castings.

Advanced Alloy Development

Researchers are working on new compositions with:

- Higher temperature capabilities

- Improved oxidation resistance

- Better thermal fatigue resistance

Additive Manufacturing

3D printing technologies are being adapted for heat resistant steel components, offering:

- Complex geometries not possible with traditional casting

- Reduced material waste

- Faster prototyping capabilities

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878