Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

Introduction to Alloy Steel Material Tray Castings

Alloy steel material tray castings represent a significant advancement in the field of industrial manufacturing, offering enhanced durability, strength, and versatility. These castings are widely used in various industries, including automotive, aerospace, and construction, due to their superior mechanical properties and resistance to wear and corrosion. The selection of the right alloy steel for tray castings is crucial to ensure optimal performance and longevity of the final product.

Key Features of Alloy Steel Material Tray Castings

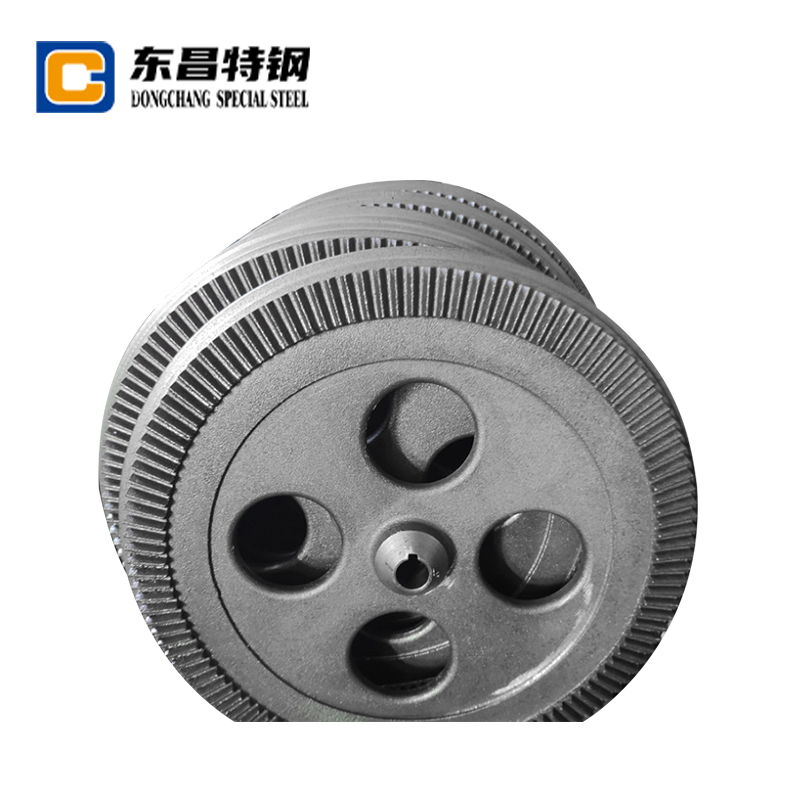

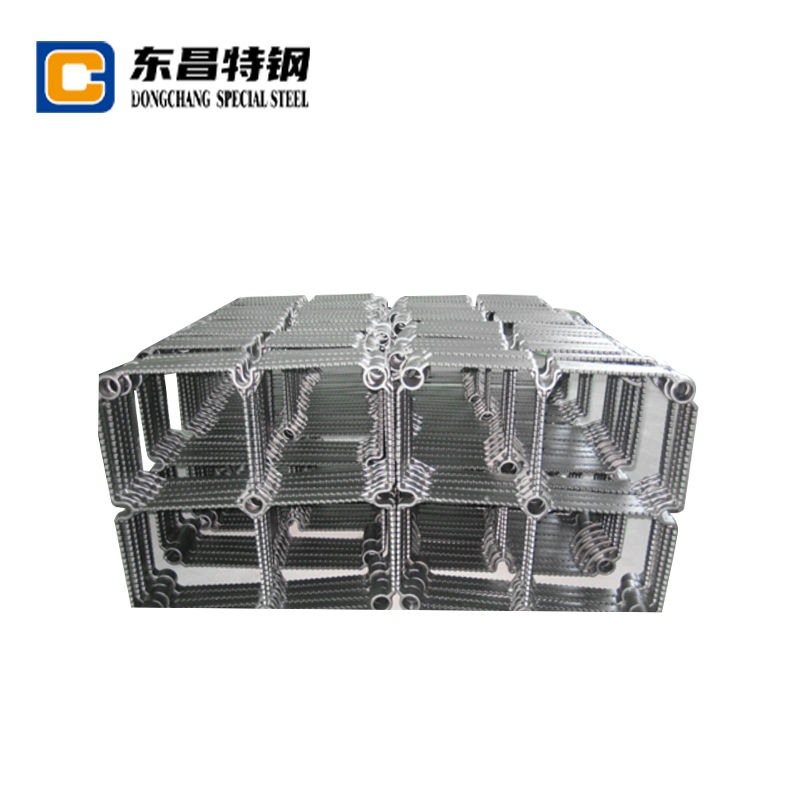

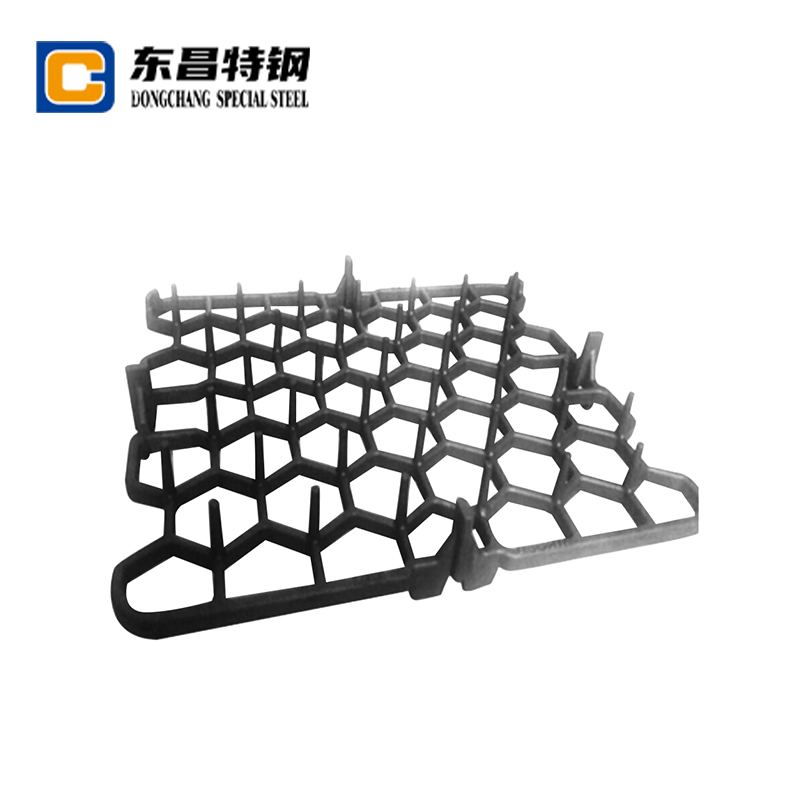

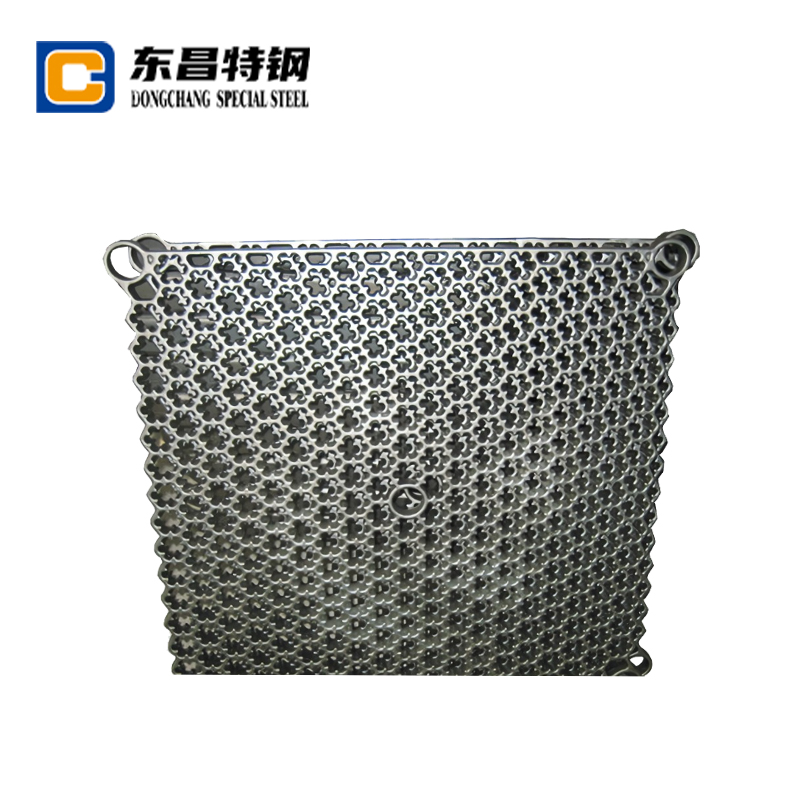

Alloy steel tray castings are characterized by their high strength-to-weight ratio, excellent fatigue resistance, and superior toughness. These properties make them ideal for applications that require high mechanical stress and repeated loading. The use of alloying elements such as chromium, nickel, and molybdenum enhances the material's resistance to corrosion and wear, making it suitable for harsh environments . Additionally, the ability to cast complex shapes with intricate details further enhances the versatility of these castings.

Material Selection and Processing Techniques

The selection of the appropriate alloy steel for tray castings involves a thorough evaluation of the material's mechanical properties, chemical composition, and processing requirements. Common alloy steels used in tray castings include ZG270-500, which is known for its excellent mechanical properties and suitability for high-stress applications . The manufacturing process typically involves casting, heat treatment, and surface finishing to achieve the desired dimensional accuracy and surface quality.

Applications and Industry-Specific Uses

Alloy steel tray castings find applications in a wide range of industries. In the automotive industry, they are used in engine components, transmission parts, and structural elements. In the aerospace sector, they are employed in landing gear components, engine mounts, and structural supports. The construction industry utilizes these castings for structural supports, beams, and other load-bearing elements. The versatility of alloy steel tray castings makes them suitable for a variety of applications requiring high strength and durability.

Quality Control and Testing Methods

Ensuring the quality and reliability of alloy steel tray castings involves rigorous quality control measures and testing methods. Non-destructive testing (NDT) techniques such as ultrasonic testing, magnetic particle inspection, and dye penetrant inspection are commonly used to detect internal defects and surface imperfections . Material testing, including tensile strength, hardness, and fatigue tests, are performed to verify the material's performance under various loading conditions.

Challenges and Future Trends

Despite the advantages of alloy steel tray castings, there are challenges associated with their production and application. The high cost of raw materials and complex manufacturing processes can limit their widespread adoption. Future trends in the industry include the development of new alloying elements to enhance material properties, the adoption of advanced manufacturing technologies such as additive manufacturing, and the integration of digital tools for design and quality control. Alloy steel material tray castings represent a significant advancement in the field of industrial manufacturing, offering superior mechanical properties, durability, and versatility. The selection of the right alloy steel and manufacturing processes is crucial to ensure optimal performance and longevity of the final product. As industries continue to evolve, the development of new materials and technologies will further enhance the capabilities and applications of alloy steel tray castings. The use of alloy steel material tray castings offers significant advantages in terms of strength, durability, and versatility. The selection of the appropriate alloy steel and manufacturing processes is crucial to ensure optimal performance and longevity of the final product. As industries continue to evolve, the development of new materials and technologies will further enhance the capabilities and applications of alloy steel tray castings.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878