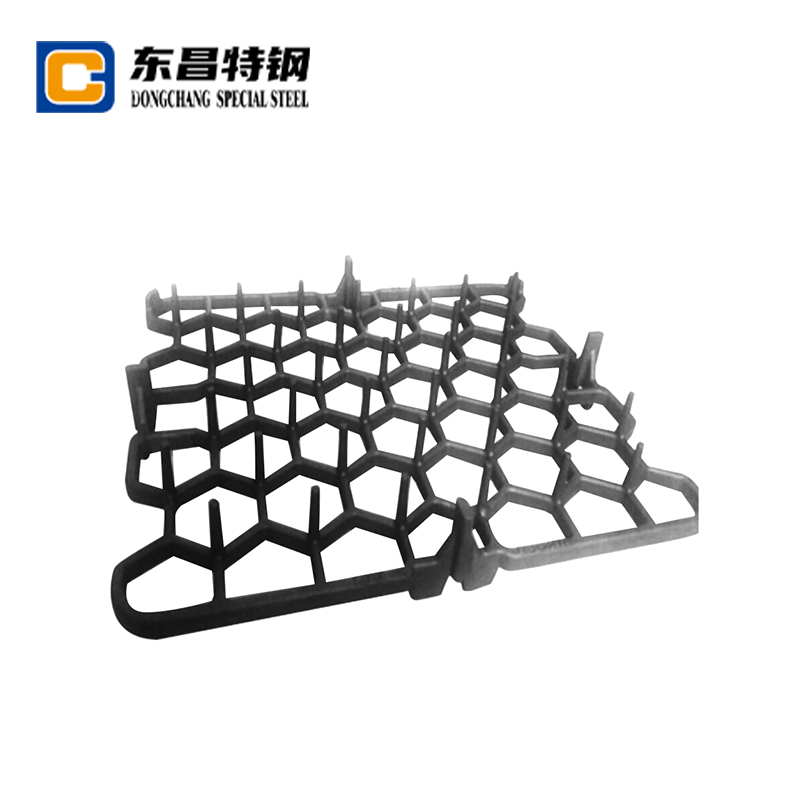

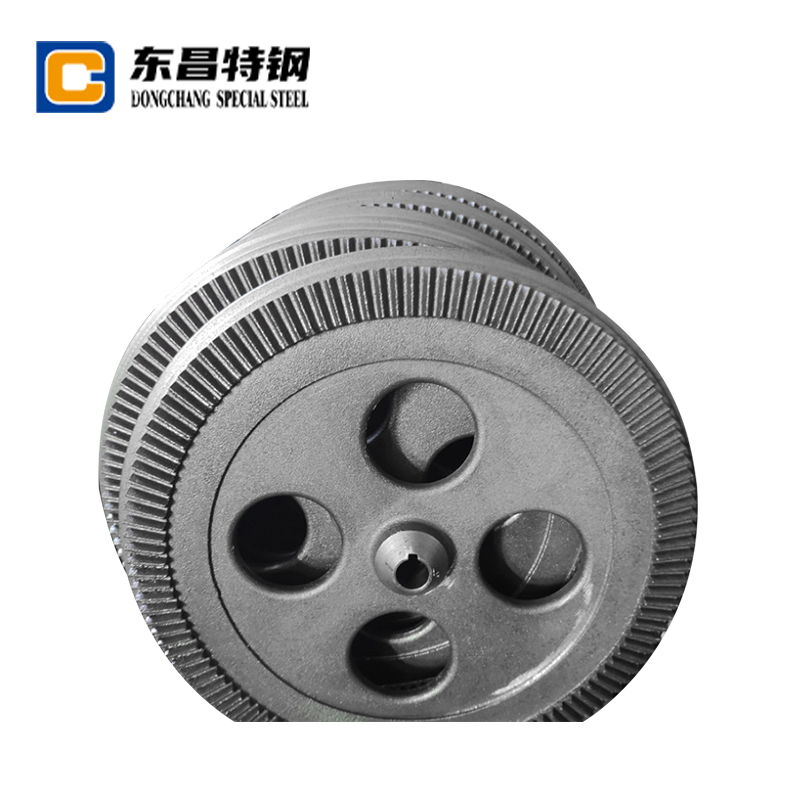

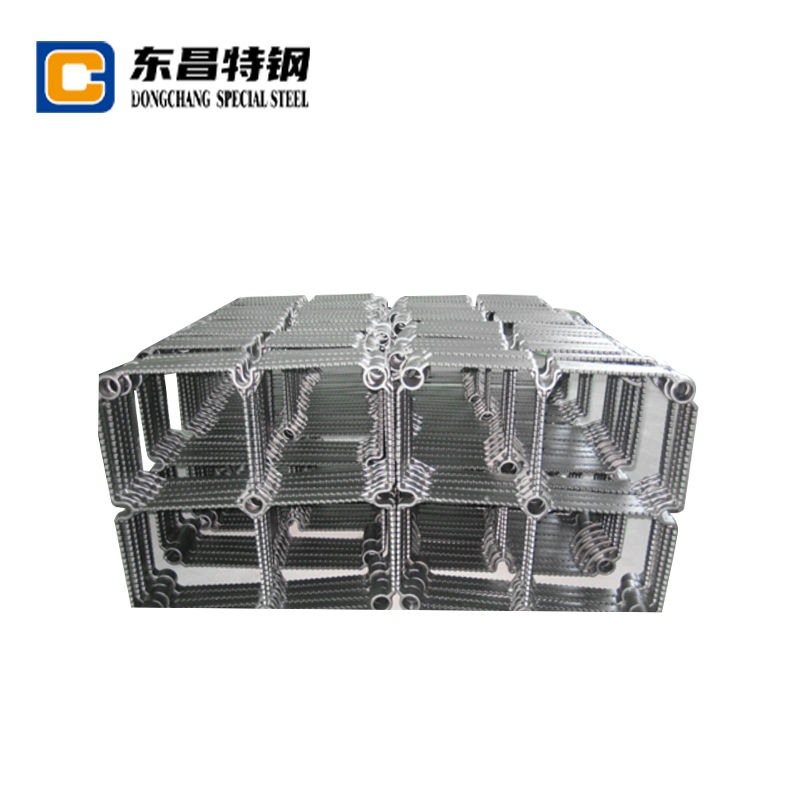

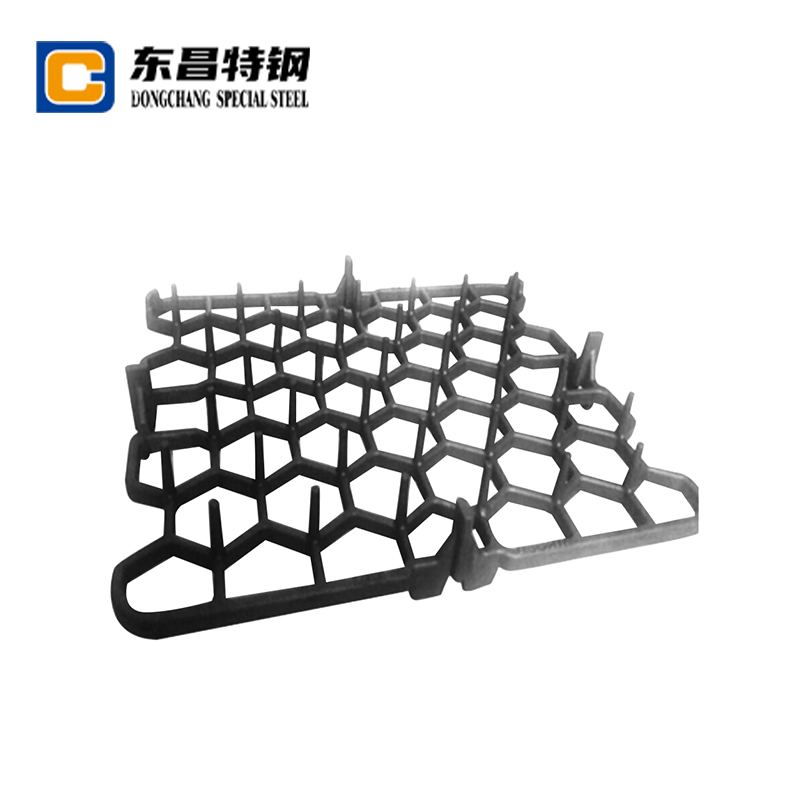

Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

The casting industry, a foundational pillar of modern manufacturing, is undergoing a profound transformation. As global environmental concerns and regulatory pressures intensify, the traditional image of foundries as high-emission, resource-intensive operations is rapidly changing. Today, the focus is squarely on sustainability, driven by the critical need for a green casting industry recycling and energy efficiency model. This shift is not merely a trend but a fundamental reorientation toward practices that reduce environmental impact, conserve resources, and improve economic viability. This article delves into the core practices and significant challenges shaping this new era of green casting.

The Imperative for a Sustainable Casting Industry

For decades, the casting process has been a major consumer of energy and raw materials, producing significant waste streams and emissions. The move towards green casting is an essential response to this legacy. It is motivated by several key factors: tightening government regulations on emissions and waste disposal, a growing demand from consumers and partners for environmentally responsible products, and the long-term financial benefits of resource efficiency. Foundries that embrace this change are not just complying with new rules; they are positioning themselves as forward-thinking leaders in a competitive market.

Adopting Recycling Practices in the Green Casting Industry

Recycling is a cornerstone of any sustainable manufacturing process, and the casting industry is no exception. Foundries are implementing a range of innovative recycling strategies to minimize their footprint:

-

Scrap Metal Reuse

Foundries have a long history of melting down and reusing scrap metal. However, modern green practices involve more sophisticated sorting and treatment of scrap to ensure higher quality and purity in the final cast product. This closed-loop system significantly reduces the demand for virgin raw materials.

-

Sand Reclamation

The casting process uses vast quantities of sand to create molds. Traditionally, this sand was discarded after a single use. Today, advanced sand reclamation systems clean and recondition used sand, allowing it to be reused multiple times. This practice dramatically cuts down on waste and the environmental impact associated with new sand mining and transportation.

-

Water Conservation

Foundries consume large amounts of water for cooling and other processes. By implementing closed-loop cooling systems and sophisticated water treatment and recycling technologies, companies can significantly reduce their overall water consumption and discharge.

The integration of these recycling initiatives is a vital component of fostering a truly sustainable green casting industry recycling and energy efficiency framework.

Enhancing Energy Efficiency Through Smart Production

Beyond recycling, energy consumption is another critical area where foundries are making significant strides. Energy-saving measures not only help the environment but also lead to substantial cost savings.

-

Advanced Furnace Technology

Traditional cupola furnaces are being replaced by more energy-efficient induction furnaces. These furnaces offer faster melting times, greater temperature control, and significantly lower energy consumption and emissions.

-

Heat Recovery Systems

Waste heat is a byproduct of many foundry processes. New technologies capture this heat and repurpose it for other uses, such as preheating materials or heating water for facility use.

-

Process Optimization

Foundries are using data analytics and smart sensors to monitor and optimize their production lines. By identifying and eliminating inefficiencies, they can reduce energy waste at every stage of the manufacturing process.

These technological and operational improvements are essential for a successful green casting industry recycling and energy efficiency strategy, ensuring that sustainable practices are both environmentally sound and economically viable.

The Challenges and Future Outlook

While the path to green casting is clear, it is not without its hurdles. The transition requires substantial initial investment in new equipment and technology. Implementing these changes also demands a new skill set from the workforce, necessitating investment in training and education. Furthermore, the complexities of managing new recycling and energy systems can pose operational challenges.

Despite these difficulties, the long-term benefits are undeniable. The future of the casting industry lies in innovation, collaboration, and a steadfast commitment to sustainability. By embracing circular economy principles, investing in clean technologies, and fostering a culture of continuous improvement, the industry can meet its environmental obligations while securing its own prosperous future. The move toward green casting is more than a series of isolated actions; it is the collective commitment to building a more resilient, responsible, and sustainable world.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878