Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

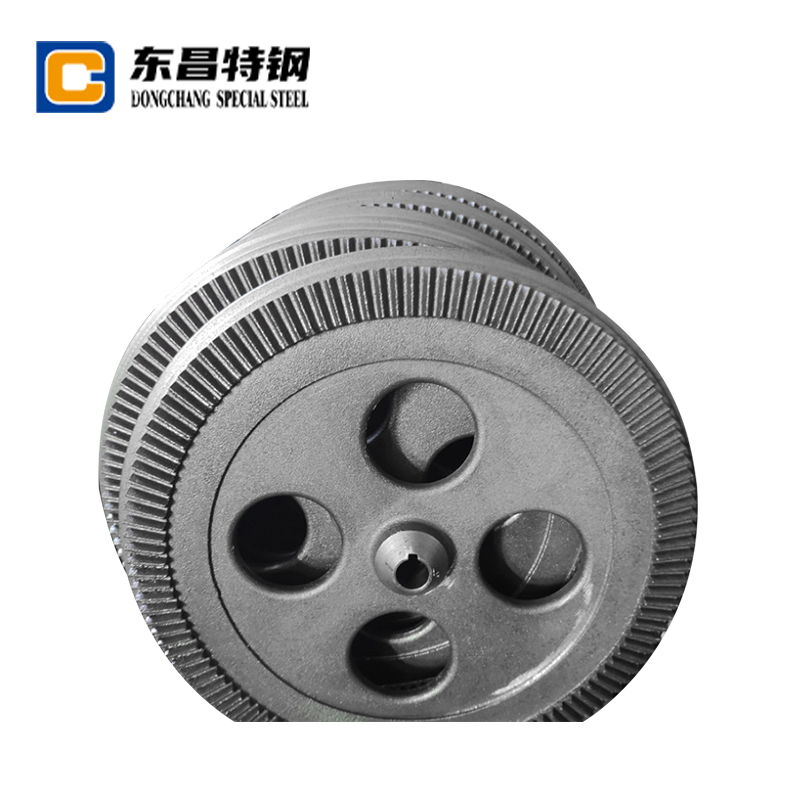

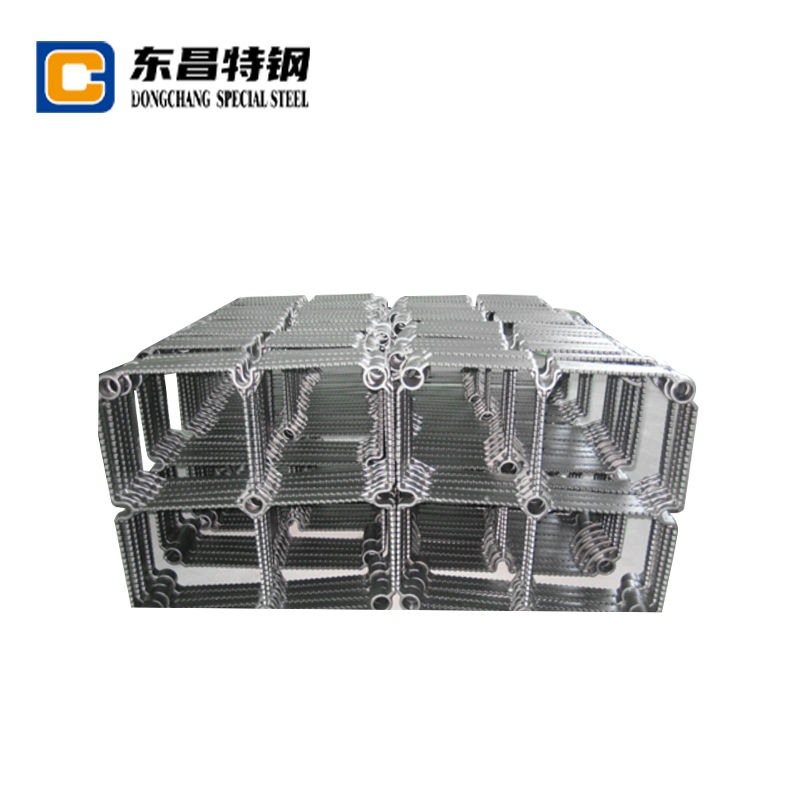

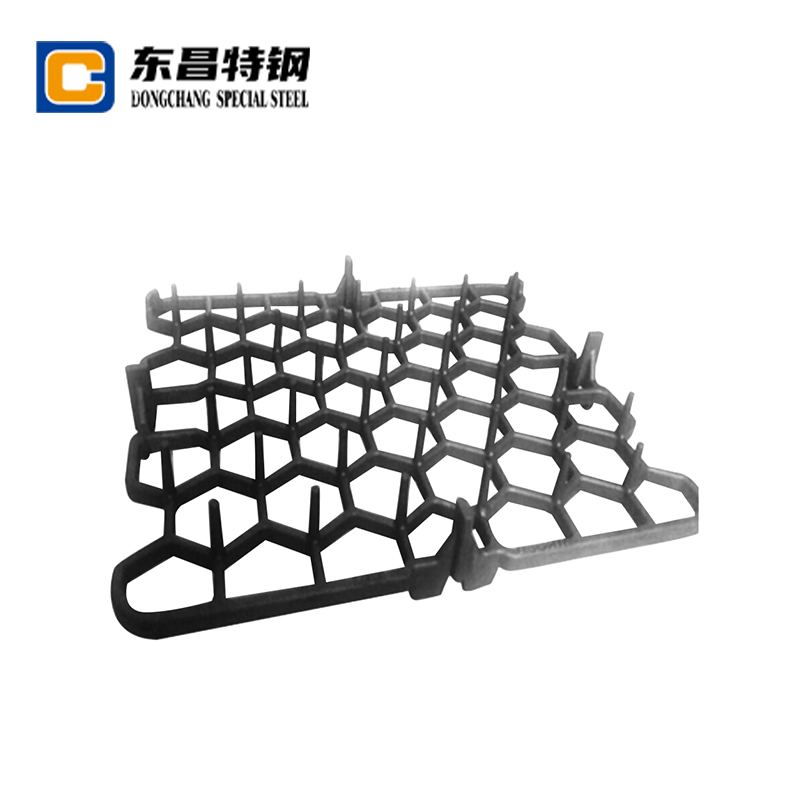

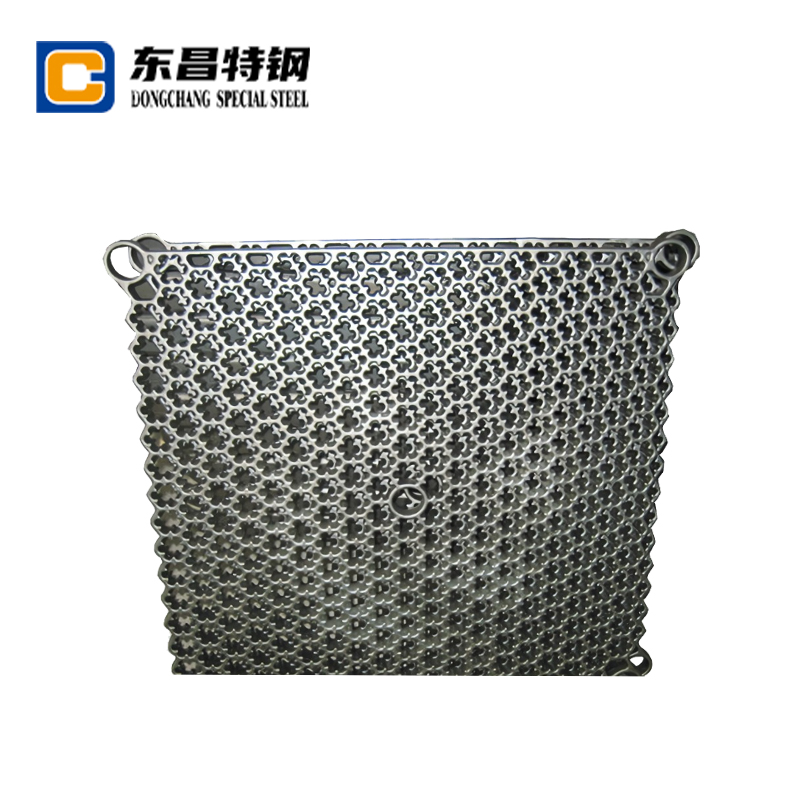

Overview of Alloy Steel Material Tray Castings

Alloy steel material tray castings are widely used in industrial sectors such as chemical processing, heavy machinery, mining, and heat treatment. Their main advantage lies in combining the structural strength of steel with enhanced properties such as corrosion resistance, high-temperature performance, and wear resistance. By carefully adjusting the type and content of alloying elements, manufacturers can tailor the properties of these tray castings to meet specific operational needs.

- High-temperature resistant alloy steel tray castings are designed to maintain mechanical stability at elevated temperatures.

- Corrosion-resistant alloy steel tray castings for chemical industry ensure long-term durability in corrosive environments.

- Custom alloy steel tray castings for heavy machinery are engineered for high impact and stress resistance.

- Alloy steel tray castings with enhanced wear resistance extend service life in abrasive conditions.

- Alloy steel tray castings for mining equipment are built to withstand harsh mechanical and environmental forces.

Understanding how alloying elements such as chromium, nickel, and molybdenum influence these properties is essential for selecting the right tray casting for industrial applications.

Impact of Chromium on Tray Castings

Chromium is one of the most critical elements for improving corrosion resistance and surface hardness in alloy steel material tray castings. Higher chromium content allows the formation of a passive oxide layer, preventing oxidation and chemical attack. This is especially important for corrosion-resistant alloy steel tray castings for chemical industry, which operate in acidic or alkaline environments.

- Chromium increases wear resistance, extending the service life of tray castings exposed to friction or abrasive materials.

- It contributes to higher hardness after heat treatment, improving load-bearing capacity.

- Excess chromium can make the material less ductile, so balance is necessary based on application.

| Chromium Content (%) | Corrosion Resistance | Hardness |

| 2 | Moderate | Low |

| 5 | High | Medium |

| 10 | Very High | High |

Role of Nickel in Tray Castings

Nickel enhances toughness, impact resistance, and ductility of alloy steel material tray castings, making it crucial for custom alloy steel tray castings for heavy machinery. Nickel strengthens the austenite phase, which improves performance in low-temperature environments and under dynamic loads.

- Nickel maintains structural integrity under repeated stress, reducing the risk of cracking.

- It works synergistically with chromium to improve both corrosion resistance and mechanical performance.

- Applications requiring frequent load changes or vibration benefit greatly from higher nickel content.

| Nickel Content (%) | Toughness | Ductility |

| 2 | Moderate | Moderate |

| 5 | High | High |

| 10 | Very High | Very High |

Influence of Molybdenum on High-Temperature Performance

Molybdenum improves high-temperature strength and wear resistance in alloy steel material tray castings. It helps prevent softening at elevated temperatures, which is essential for high-temperature resistant alloy steel tray castings and alloy steel tray castings for mining equipment.

- It enhances creep resistance, allowing tray castings to maintain shape under long-term heat exposure.

- Molybdenum synergizes with chromium to improve both corrosion resistance and strength at high temperatures.

- Essential in applications involving high-pressure, abrasive, or thermal cycling conditions.

| Molybdenum Content (%) | High-Temperature Strength | Wear Resistance |

| 0.5 | Moderate | Moderate |

| 1.0 | High | High |

| 2.0 | Very High | Very High |

Comparative Analysis of Alloying Elements

When designing alloy steel material tray castings, understanding the comparative effects of chromium, nickel, and molybdenum helps optimize performance for different industries.

| Alloying Element | Primary Property Enhanced | Recommended Application | Notes |

| Chromium | Corrosion Resistance | Chemical Industry | Best for acidic or alkaline environments |

| Nickel | Toughness & Ductility | Heavy Machinery | Reduces cracking under dynamic load |

| Molybdenum | High-Temperature Strength | Mining & High-Temperature Applications | Improves wear resistance and creep strength |

Industry Applications

- Chemical Industry: Uses corrosion-resistant alloy steel tray castings for chemical industry to withstand aggressive chemical exposure.

- Heavy Machinery: Employs custom alloy steel tray castings for heavy machinery for improved toughness and impact resistance.

- Mining: Utilizes alloy steel tray castings for mining equipment that resist abrasion and high pressure.

- High-Temperature Applications: Uses high-temperature resistant alloy steel tray castings and alloy steel tray castings with enhanced wear resistance for thermal stability and long-term durability.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878