Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

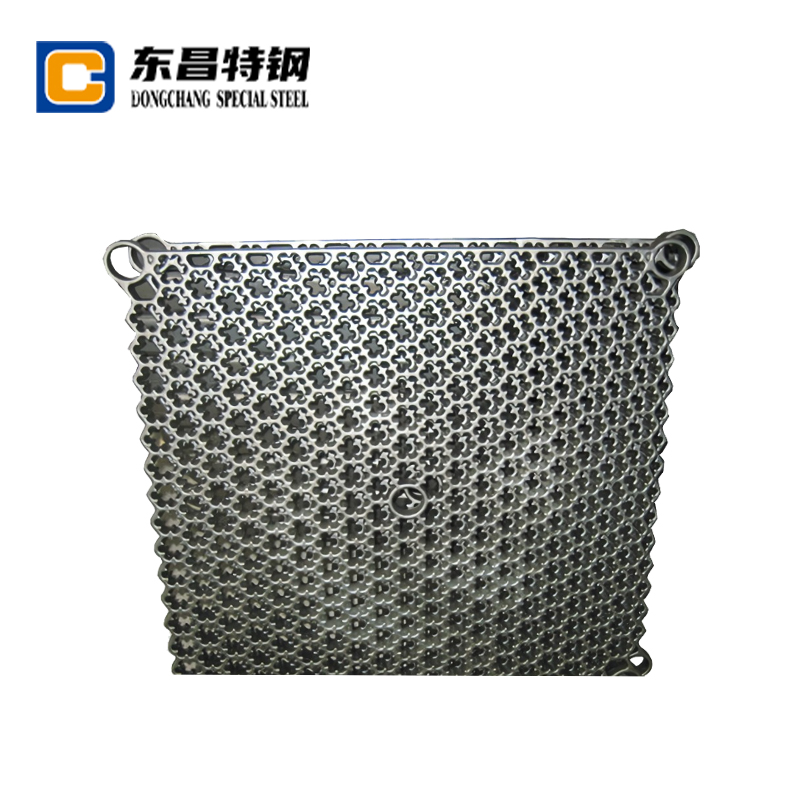

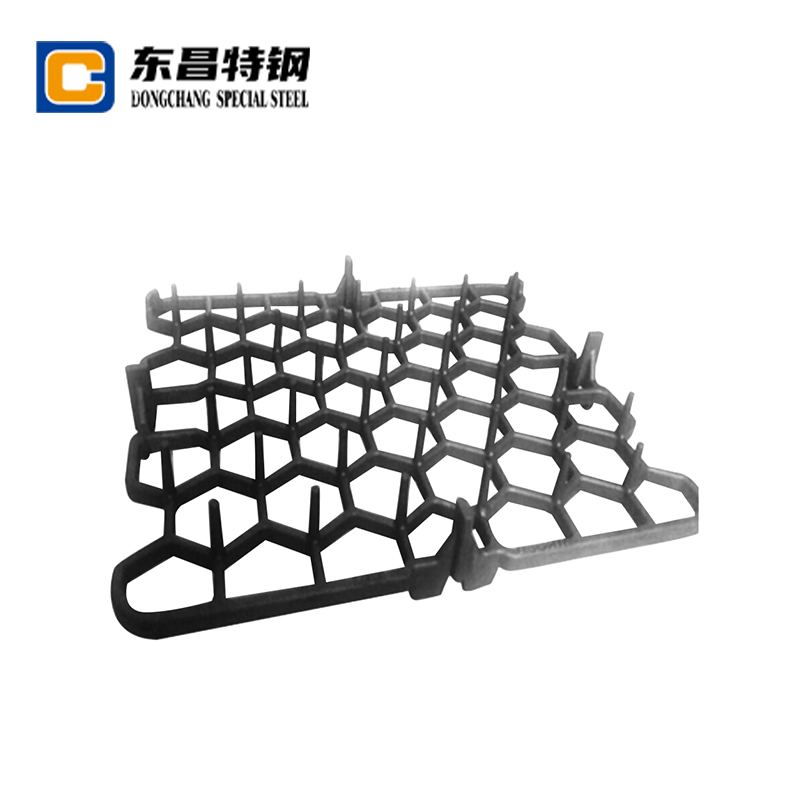

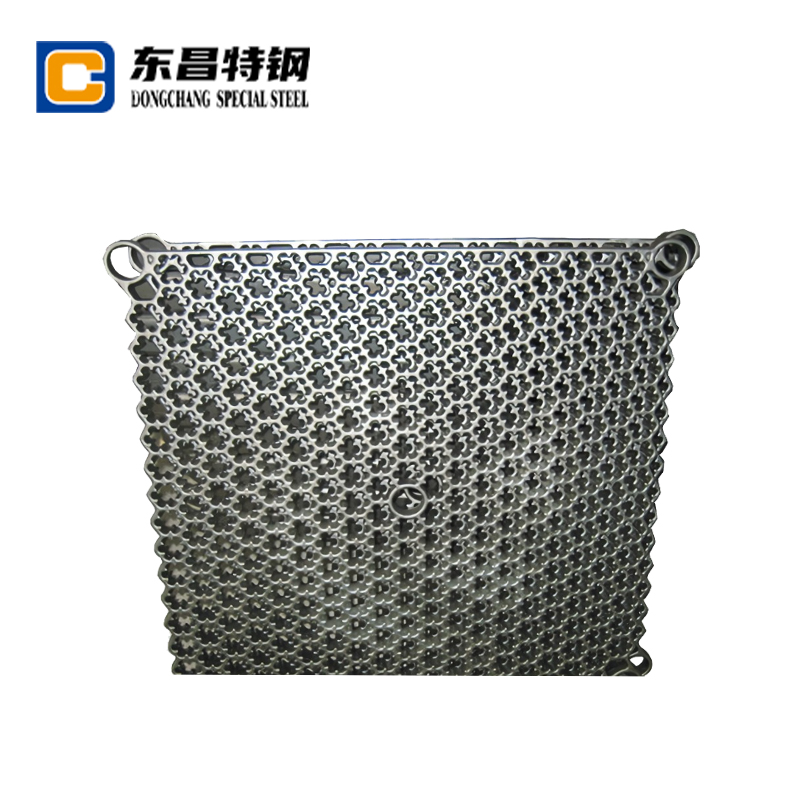

Alloy steel material tray castings are essential components in industries that require high strength, durability, and resistance to wear and extreme conditions. These castings are widely used in heavy machinery, mining, construction, and industrial processing due to their superior mechanical properties compared to standard carbon steel. By incorporating elements like chromium, nickel, and molybdenum, alloy steel tray castings achieve enhanced hardness, toughness, and corrosion resistance, making them ideal for demanding environments.

1. High-Strength Alloy Steel Tray Castings for Industrial Use

What Makes Them High-Strength?

High-strength alloy steel tray castings are engineered to withstand extreme mechanical stress, high loads, and repetitive impacts. The addition of alloying elements such as manganese, vanadium, and boron enhances tensile strength and fatigue resistance, making them suitable for critical industrial applications.

Key Benefits:

Superior Load-Bearing Capacity – Ideal for conveyor systems, gear trays, and structural supports.

Wear Resistance – Extended service life even in abrasive environments.

Heat Treatment Compatibility – Can be further hardened or tempered for specific needs.

Common Applications:

Mining & Material Handling – Used in ore chutes, hoppers, and conveyor trays.

Automotive & Aerospace – Components requiring high strength-to-weight ratios.

Industrial Machinery – Gearboxes, hydraulic system trays, and machine bases.

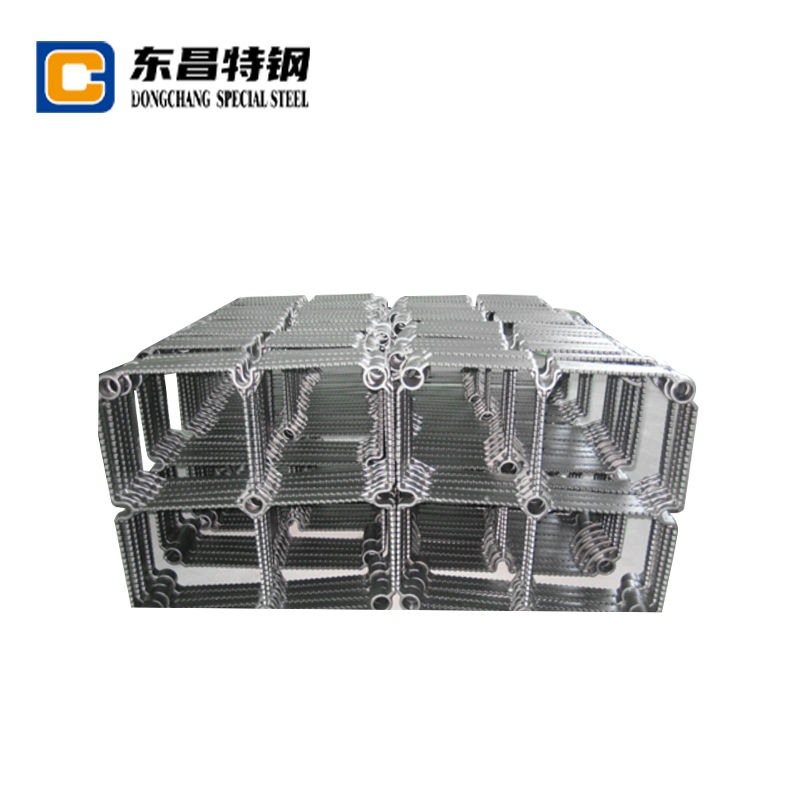

Heavy Duty Precision Casting Material Tray Castings

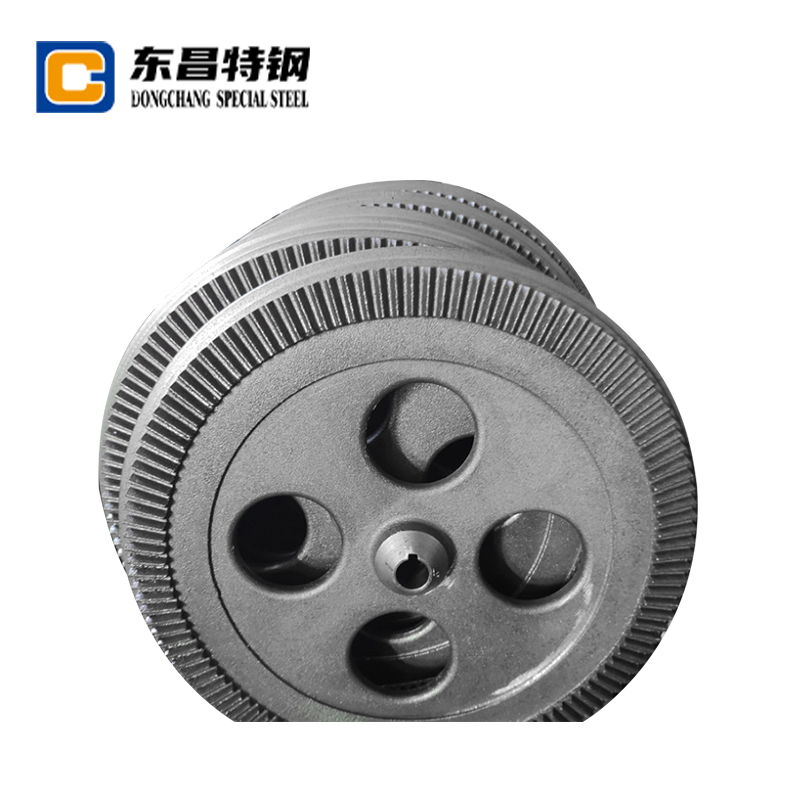

2. Durable Alloy Steel Casting Trays for Heavy-Duty Applications

Why Choose Durable Alloy Steel Castings?

Durability is a critical factor in heavy-duty industries where equipment faces constant wear, impact, and harsh operating conditions. Alloy steel casting trays offer exceptional toughness and longevity, reducing maintenance costs and downtime.

Key Benefits:

Impact Resistance – Withstands heavy shocks without cracking.

Corrosion & Oxidation Resistance – Suitable for outdoor and chemically aggressive environments.

Customizable Designs – Can be cast into complex shapes for specialized machinery.

Common Applications:

Construction & Earthmoving Equipment – Bucket liners, crusher trays, and excavator components.

Oil & Gas Industry – Drill rig parts, pipeline supports, and valve housings.

Power Generation – Turbine components and boiler tray systems.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878