Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

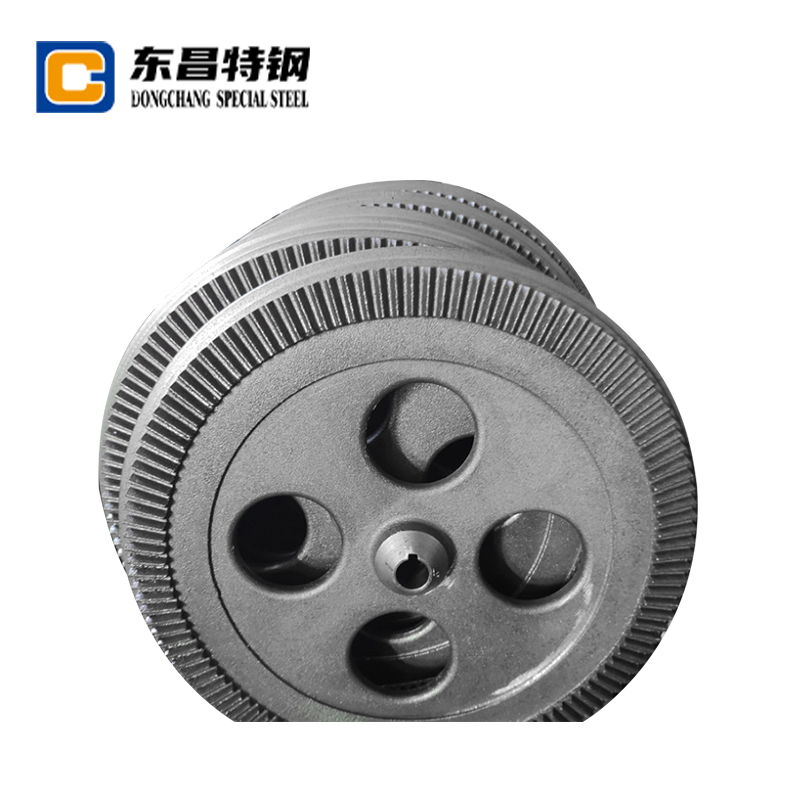

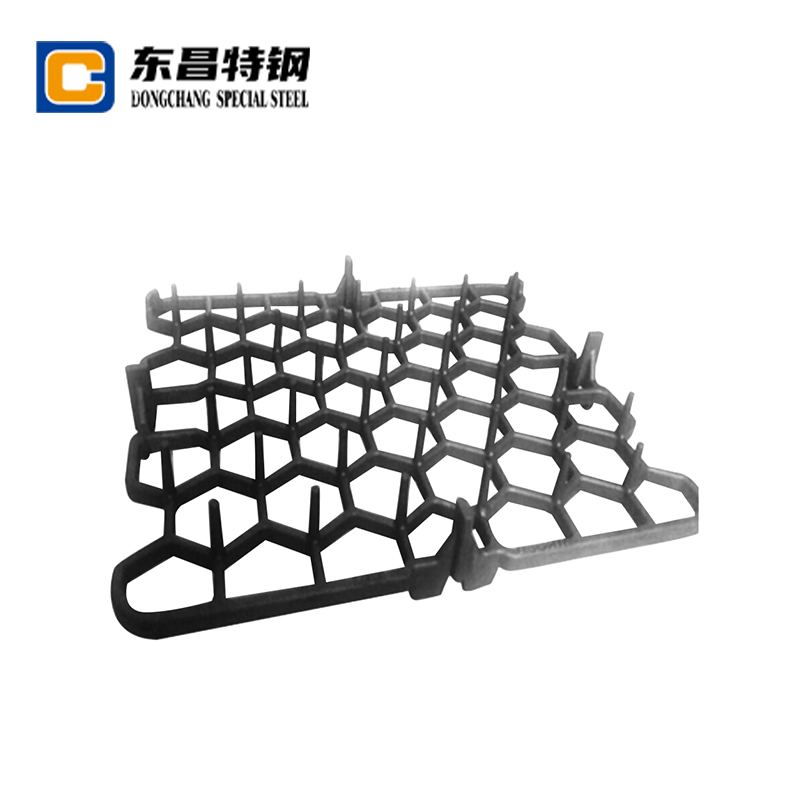

In demanding industrial environments where extreme heat and mechanical stress are common, heat resistant steel material frame castings provide the strength and durability needed to ensure long-term performance. These specialized castings are designed to withstand high temperatures, resist oxidation, and maintain structural integrity under heavy loads, making them essential for industries such as power generation, metallurgy, and chemical processing.

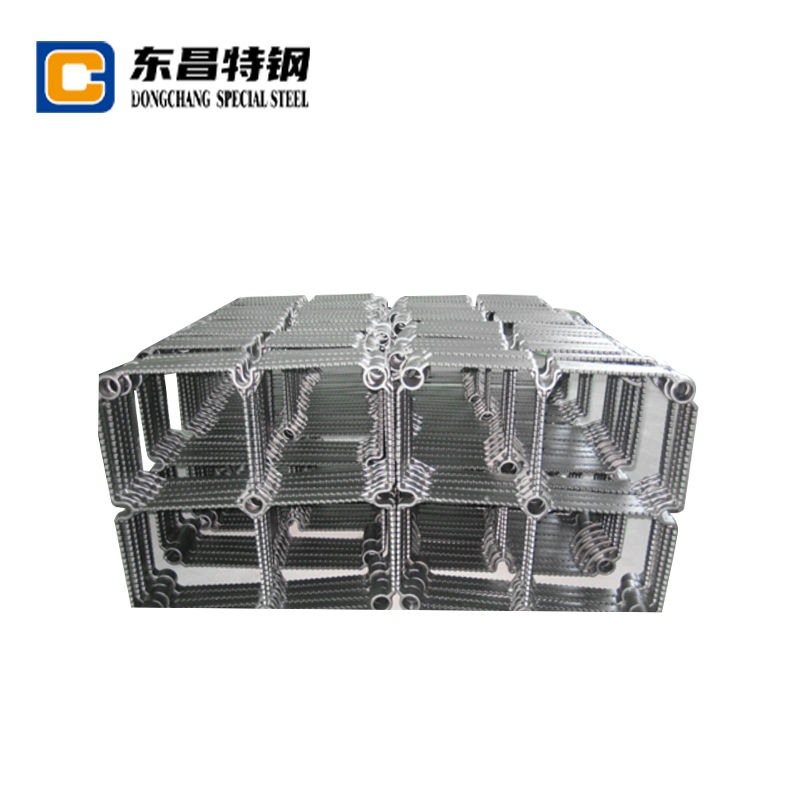

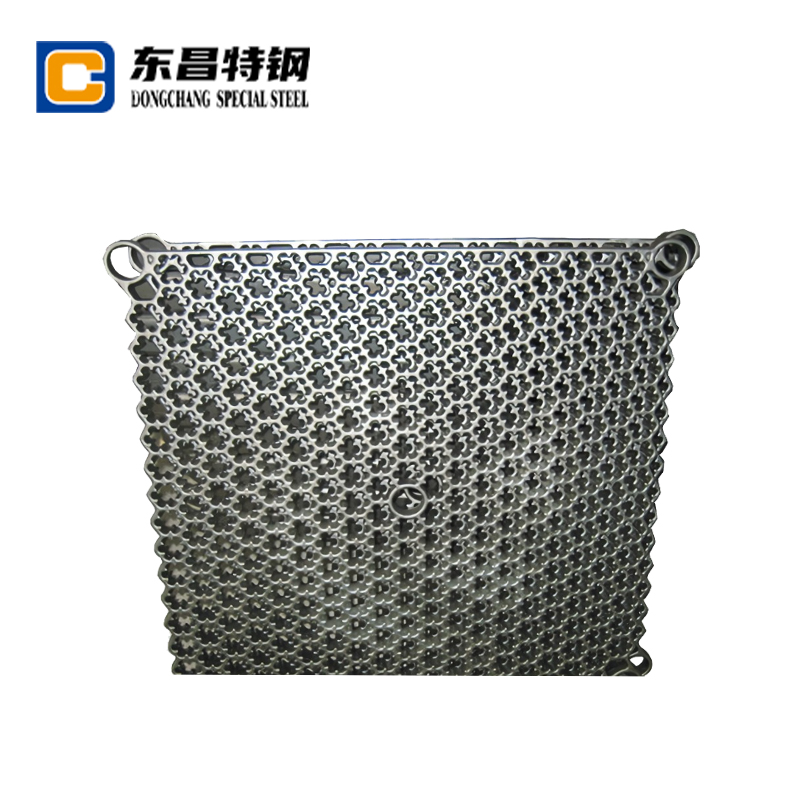

Heat Resistant Steel Casting Tray Castings

Heat Resistant Steel Casting for Industrial Frames: Strength Under Extreme Conditions

Industrial machinery operating in high-heat environments requires materials that can resist deformation, thermal fatigue, and corrosion. Heat resistant steel casting for industrial frames offers:

Exceptional Thermal Stability: Retains mechanical properties even at elevated temperatures (up to 1100°C or higher).

Oxidation & Corrosion Resistance: Prevents degradation in harsh atmospheres, such as furnaces and exhaust systems.

High Load-Bearing Capacity: Maintains structural integrity under heavy industrial loads.

Common applications include:

Furnace and boiler components

Power plant turbine frames

Petrochemical processing equipment

Aerospace and automotive heat shields

By using heat-resistant steel castings, industries can reduce maintenance costs and extend equipment lifespan.

Custom Heat Resistant Steel Frame Casting Services: Tailored Solutions for Precision Engineering

Not all industrial frames have the same requirements—some need unique shapes, specific alloy compositions, or specialized heat treatments. Custom heat resistant steel frame casting services provide tailored solutions with:

Design Flexibility: Engineers can create complex geometries to fit exact specifications.

Material Optimization: Alloy selection (e.g., ASTM A297, A608, or proprietary blends) based on temperature and stress requirements.

Advanced Manufacturing Techniques: Investment casting, sand casting, or precision machining for high-accuracy components.

Industries benefit from custom services by:

Reducing material waste with optimized designs

Improving performance with alloy-specific enhancements

Ensuring compatibility with existing machinery

For industries requiring bespoke solutions, partnering with a foundry that offers custom casting services is crucial.

High Temperature Steel Frame Casting Suppliers: Choosing the Right Partner

Selecting the right high temperature steel frame casting suppliers ensures quality, reliability, and cost-efficiency. Key factors to consider include:

Quality Certifications: ISO 9001, ASTM, or industry-specific compliance for consistent performance.

Production Capacity: Ability to handle large-scale orders with fast turnaround times.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878