Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

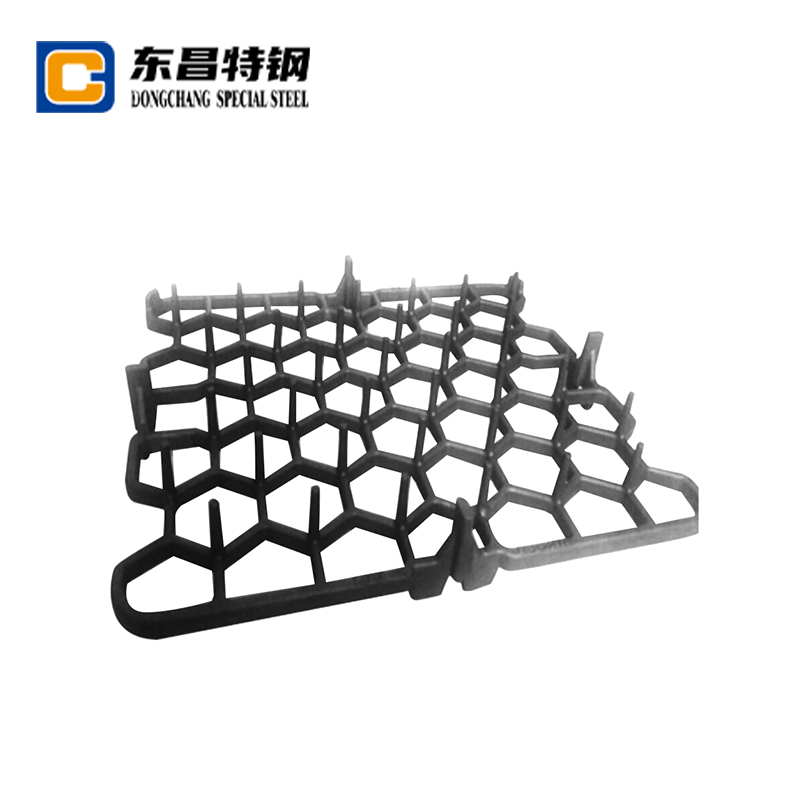

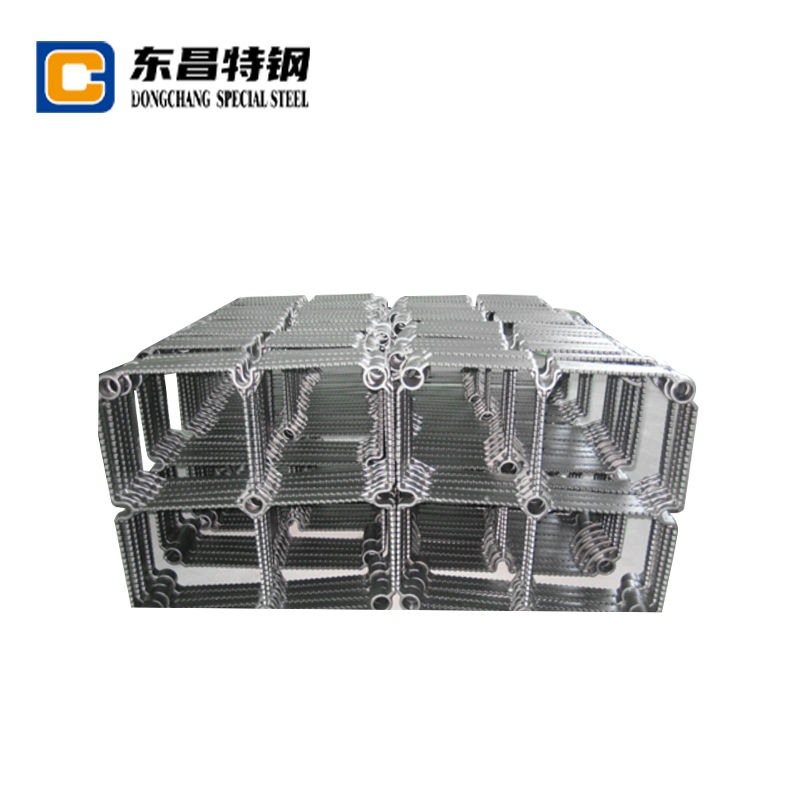

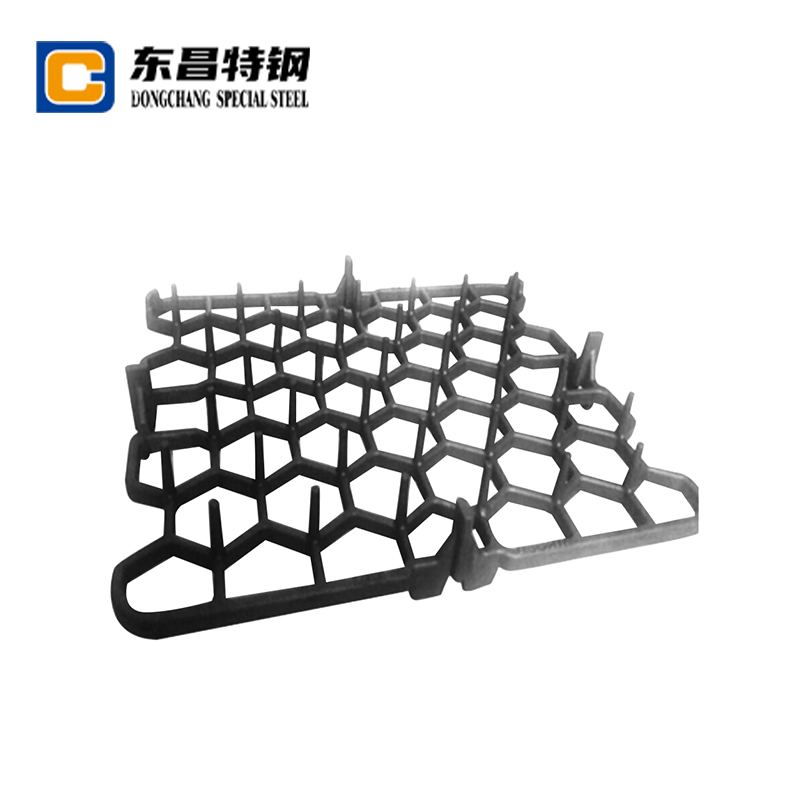

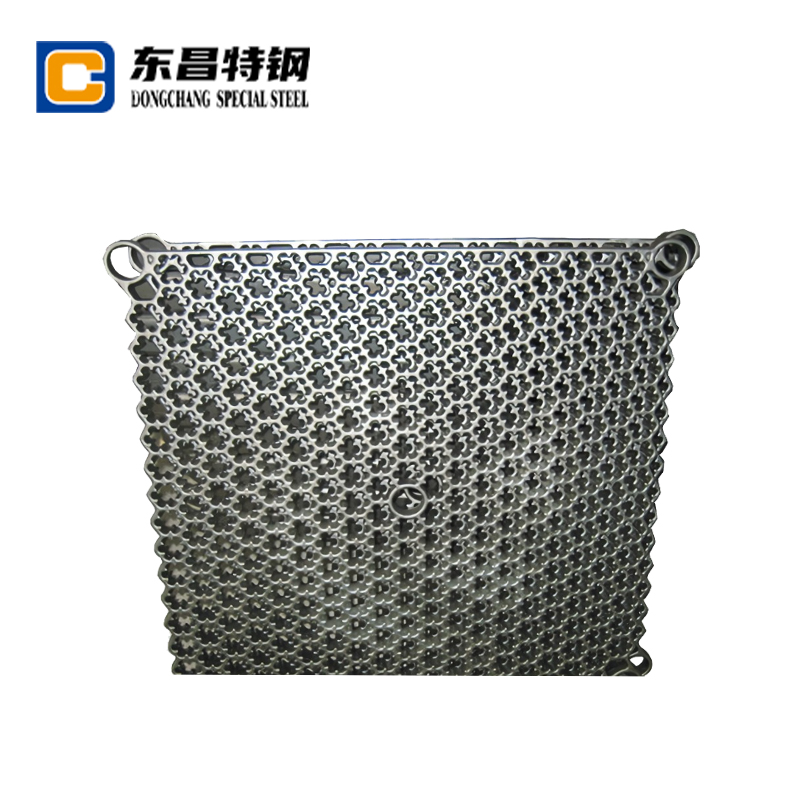

Alloy steel tray castings are essential components in numerous demanding industrial applications due to their superior performance characteristics. These castings are engineered to withstand extreme conditions, offering a blend of strength, durability, and resistance to harsh environments.

Heat-Resistant Steel Tray Castings

Alloy Steel Material Properties for Tray Castings

Alloy steel material properties for tray castings are key to their robust performance. These materials are specifically formulated to enhance mechanical and chemical characteristics beyond what standard carbon steel can offer.

- High Strength and Wear Resistance: One of the primary advantages of alloy steel is its exceptional high strength and wear resistance. This property is crucial for applications involving heavy loads, abrasive materials, or repetitive motion, where material degradation needs to be minimized.

- High Temperature and Corrosion Resistance: Alloy steels are often designed to possess excellent high temperature and corrosion resistance. This makes them ideal for environments where extreme heat or corrosive chemicals would rapidly degrade other materials. Specifically, corrosion resistance in alloy steel tray castings is achieved through the addition of specific alloying elements.

- Common Alloying Elements and Their Roles: The superior properties of alloy steel are derived from the strategic inclusion of various alloying elements.

- Chromium (Cr): Significantly enhances hardenability, wear resistance, and especially corrosion resistance.

- Molybdenum (Mo): Improves strength at high temperatures, toughness, and resistance to temper embrittlement.

- Nickel (Ni): Increases toughness, ductility, and corrosion resistance, particularly in cryogenic applications.

- Other elements like vanadium, manganese, and silicon also contribute to specific mechanical properties.

Benefits of Alloy Steel in Industrial Tray Castings

The inherent properties of alloy steel translate into significant advantages, making them a preferred choice for many industrial applications. These benefits of alloy steel in industrial tray castings offer long-term cost-effectiveness and reliability.

- Comparing Alloy Steel vs. Carbon Steel Tray Castings: When comparing alloy steel vs. carbon steel tray castings, alloy steels consistently outperform in terms of strength, hardness, and resistance to wear, high temperatures, and corrosion. While carbon steel is more economical initially, its limitations in severe environments often lead to higher replacement and maintenance costs over time.

- Long Service Life and Low Maintenance Costs: The enhanced durability and resistance to degradation of alloy steel castings contribute to a significantly long service life and low maintenance costs. This reduces downtime for repairs and replacements, leading to greater operational efficiency.

- Suitability for Harsh Environments: Alloy steel tray castings are particularly well-suited for harsh environments such as those found in the chemical processing and mining industries, where they are exposed to corrosive agents, extreme temperatures, and abrasive conditions.

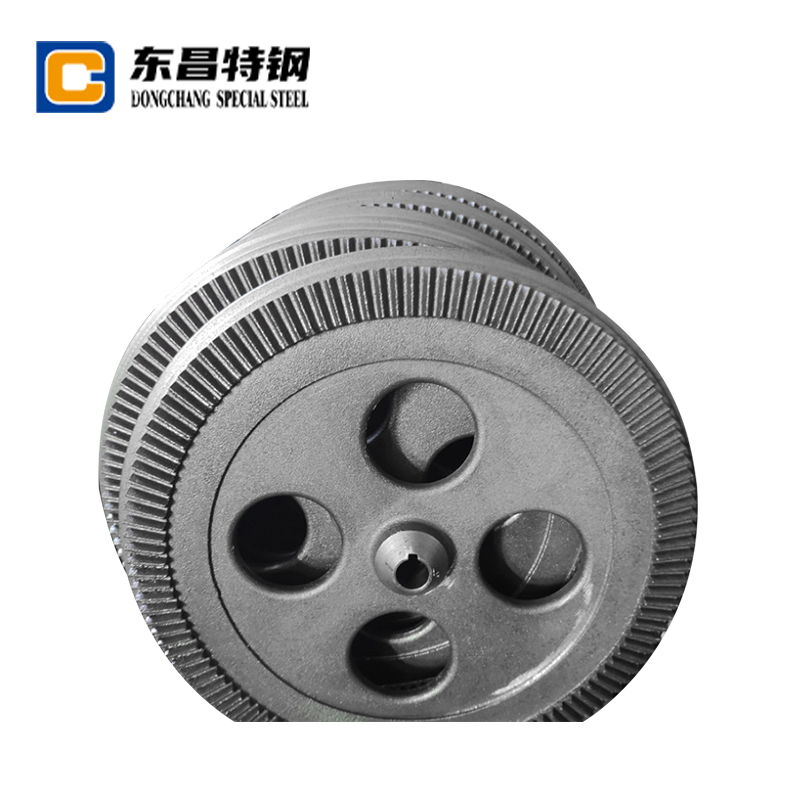

Design and Manufacturing Considerations

Producing high-quality alloy steel tray castings requires careful attention to both design and manufacturing processes. These design considerations for alloy steel tray castings are critical for optimal performance.

- Structural Design Optimization: Effective structural design optimization is paramount. This includes features like reinforcing ribs and optimized wall thickness to ensure the casting can withstand anticipated loads and stresses without compromising material integrity.

- Heat Treatment Processes for Alloy Steel Tray Castings: The final properties of alloy steel castings are heavily influenced by heat treatment processes for alloy steel tray castings. Techniques like quenching and tempering are applied to achieve desired hardness, strength, and toughness by modifying the microstructure of the steel.

- Selection of Precision Casting Techniques: The choice of casting technique also plays a vital role. Precision casting methods like sand casting are suitable for larger, more complex shapes, while investment casting (lost-wax casting) offers superior surface finish and dimensional accuracy for intricate designs.

- Machining and Finishing Techniques for Alloy Steel Trays: After casting, machining and finishing techniques for alloy steel trays are often required to achieve final dimensions and surface quality. This can include grinding, milling, and polishing.

Industrial Applications

The unique combination of properties makes alloy steel tray castings indispensable across a broad spectrum of industries. These are some key applications of alloy steel tray castings in heavy industries.

- Trays in Heavy Machinery and Mining Equipment: Alloy steel tray castings are extensively used as wear plates, liners, and other critical components in heavy machinery and mining equipment, where they endure extreme abrasion and impact.

- Corrosion-Resistant Trays in the Chemical Industry: In the chemical industry, these castings serve as corrosion-resistant trays and containers for handling aggressive chemicals at varying temperatures, ensuring operational safety and longevity.

- Energy Sector (e.g., Boilers, Reactor Components): The energy sector, including applications in boilers and reactor components, relies on alloy steel castings for their ability to withstand high temperatures and pressures while maintaining structural integrity.

Quality Control Standards for Alloy Steel Casting Production

Maintaining the integrity and performance of alloy steel tray castings necessitates stringent quality control standards for alloy steel casting production. This includes material composition verification, non-destructive testing (such as ultrasonic testing and radiography) for internal defects, dimensional inspection, and mechanical property testing. Adherence to these standards ensures that the manufactured castings meet the demanding requirements of their intended industrial applications, guaranteeing reliability and safety.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878