Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

Industrial steel casting trays are critical components in heavy machinery, CNC automation, and high-speed manufacturing systems. As industries evolve, the demand for specialized trays—whether heat-resistant, vibration-dampening, or eco-friendly—has grown significantly.

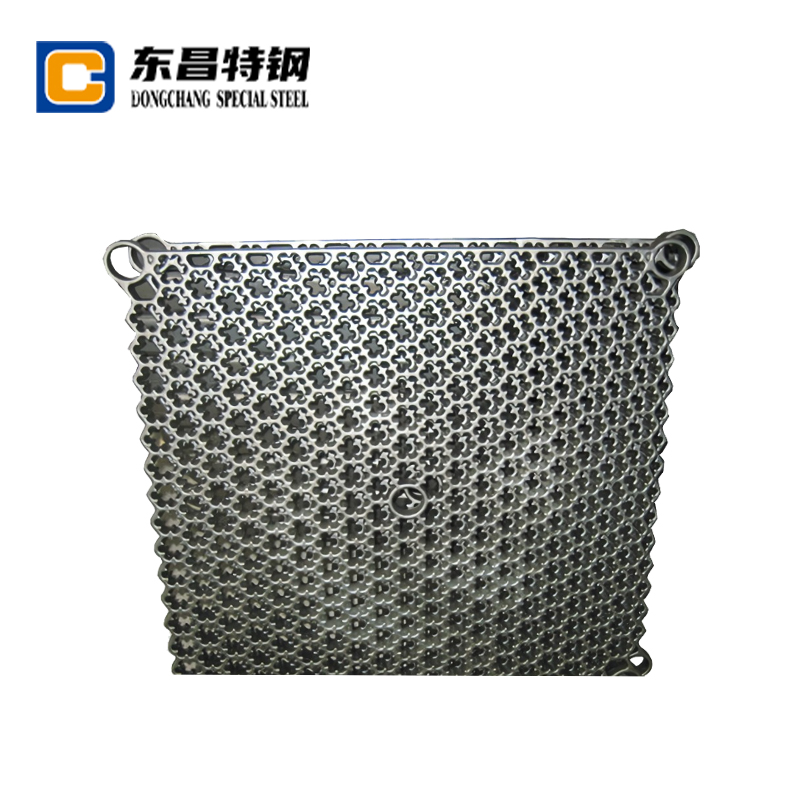

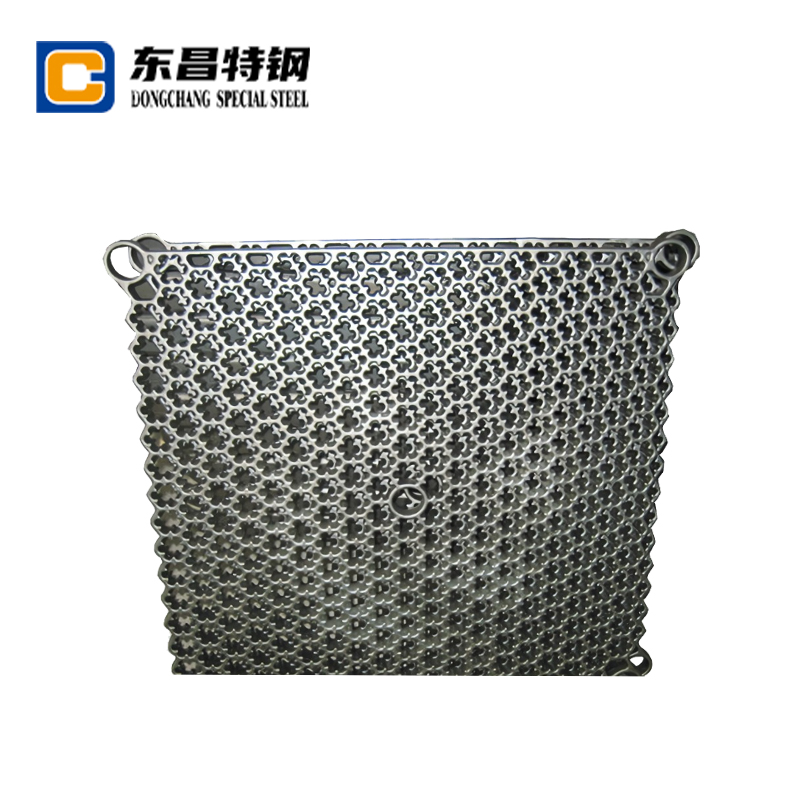

Heavy Duty Precision Casting Material Tray Castings

1. High-Temperature Industrial Steel Casting Trays for Heavy Machinery

Why High-Temperature Resistance Matters

Heavy machinery in foundries, metal processing, and power generation operates under extreme heat, requiring steel casting trays that withstand thermal stress without warping.

Key Features & Applications:

Material Composition: Alloy steels with chromium and molybdenum for enhanced heat resistance.

Common Uses: Furnace loading, forging equipment, and heat treatment processes.

Performance Benefits: Reduced thermal expansion, prolonged lifespan in high-heat environments.

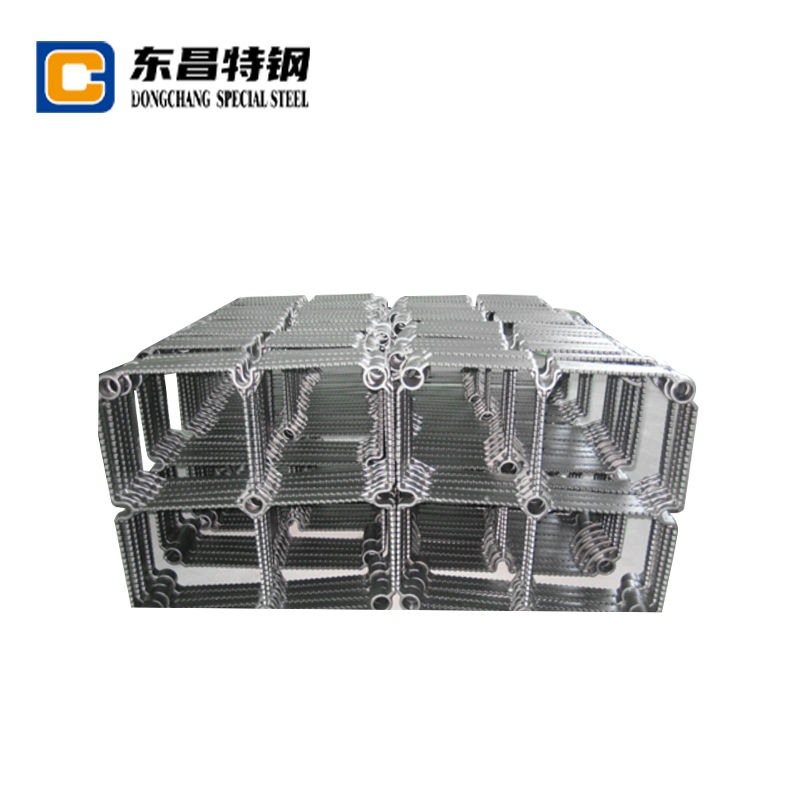

2. Custom Steel Casting Trays for CNC and Automation Machinery

The Rise of Precision Manufacturing

As CNC machining and robotic automation advance, custom-fit steel casting trays ensure seamless material handling and precision alignment.

Key Features & Applications:

Modular Designs: Adjustable dimensions for different CNC tooling requirements.

Surface Finishes: Machined smoothness to prevent part abrasion.

Industry Applications: Automotive part machining, aerospace component fabrication.

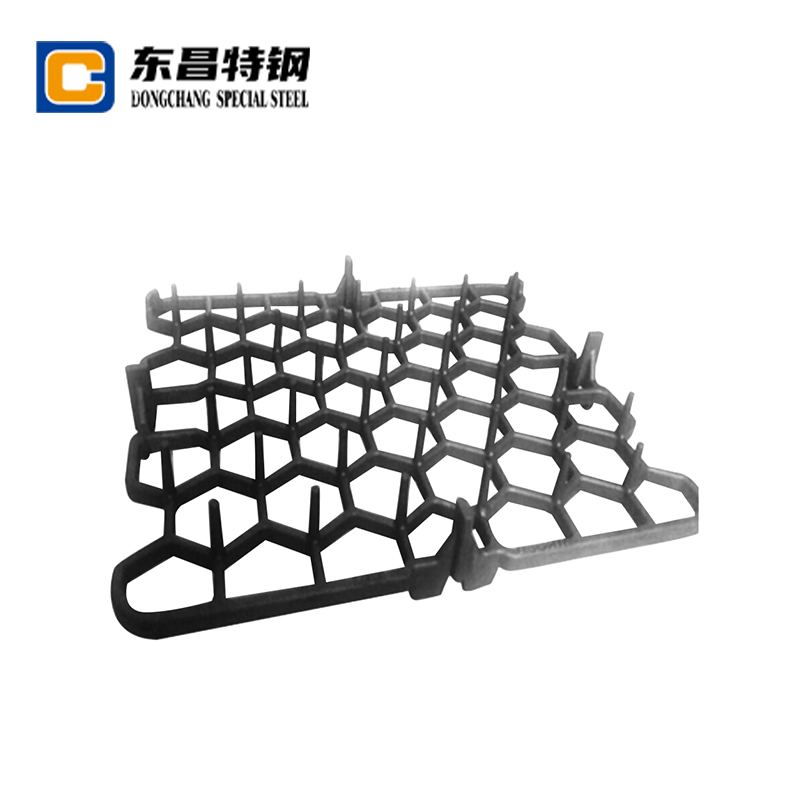

3. Green Steel Casting Trays for Sustainable Manufacturing

The Shift Toward Eco-Friendly Industrial Solutions

With increasing emphasis on reducing carbon footprints, manufacturers are adopting sustainable steel casting methods.

Key Features & Applications:

Recycled Steel Content: High percentage of post-consumer scrap metal.

Energy-Efficient Production: Use of electric arc furnaces (EAFs) over traditional blast furnaces.

Industry Adoption: Green-certified factories, eco-conscious automotive suppliers.

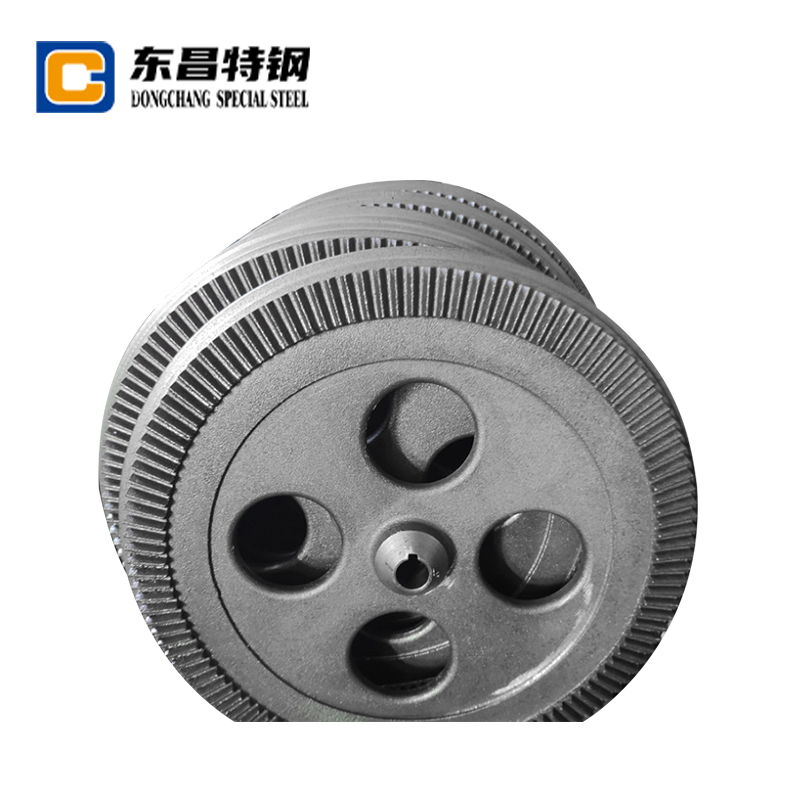

4. Vibration-Resistant Steel Casting Trays for High-Speed Machinery

Stability in Dynamic Industrial Environments

High-speed machinery, such as turbines and stamping presses, generates significant vibrations, necessitating trays that minimize resonance.

Key Features & Applications:

Damping Structures: Ribbed or weighted bases to absorb shocks.

Material Hardness: Case-hardened steel to resist micro-fractures from constant stress.

Primary Uses: High-RPM equipment, precision engineering workshops.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878