Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

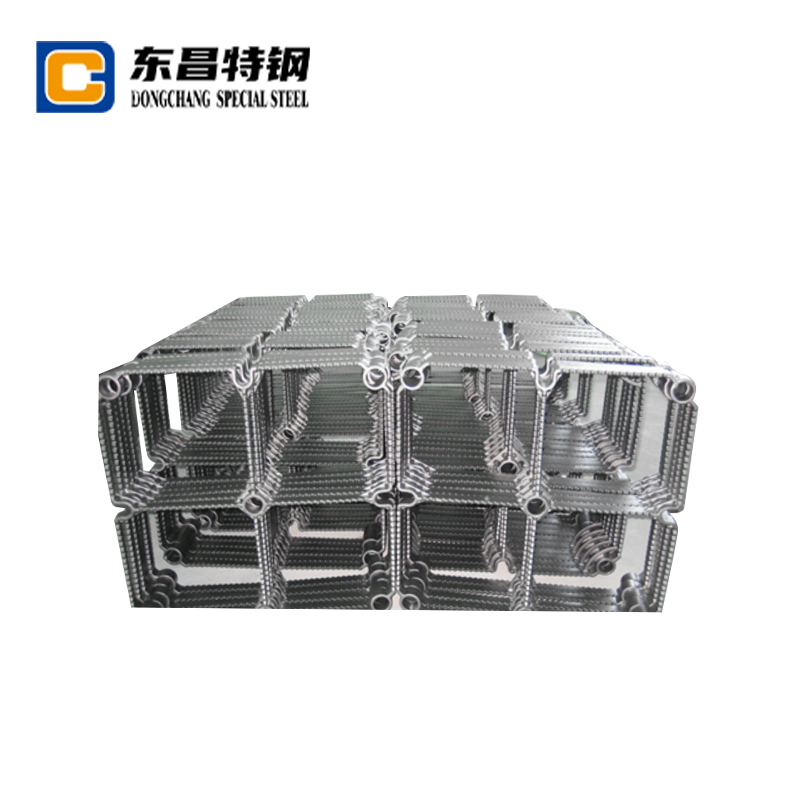

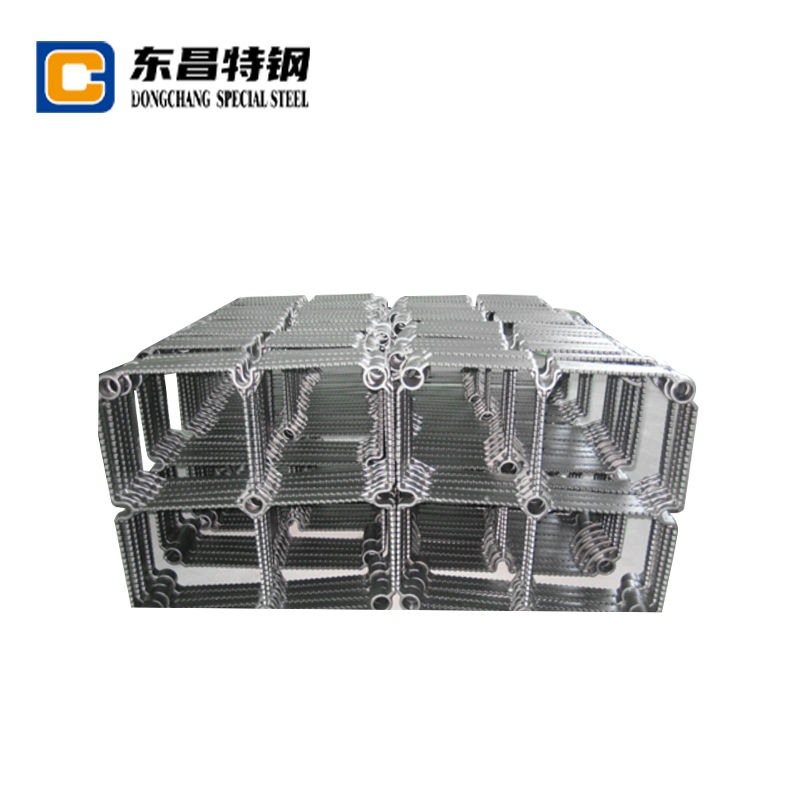

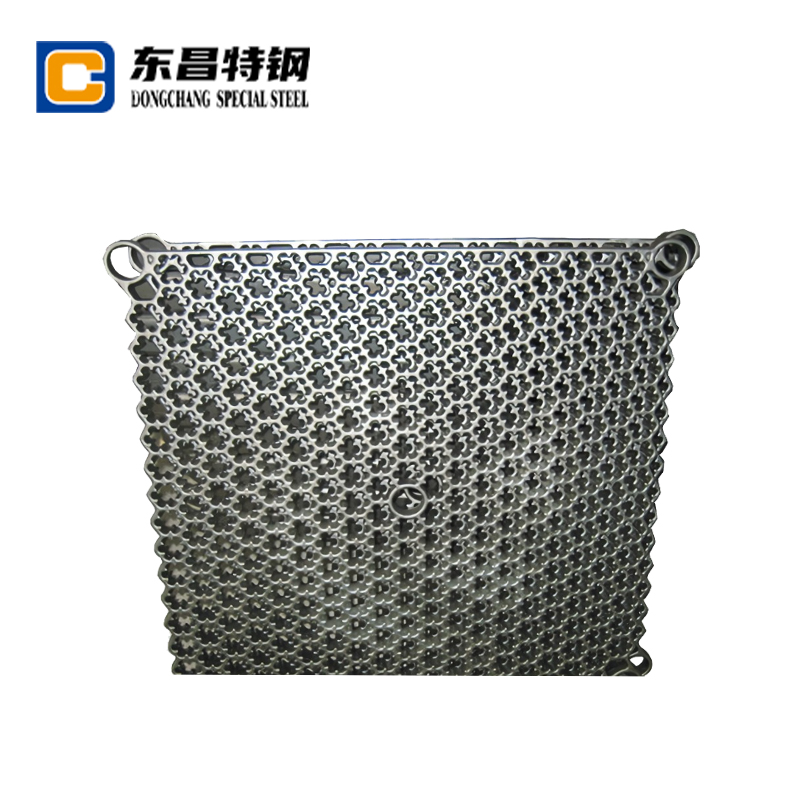

Alloy steel tray castings are essential in heavy-duty industries due to their strength, durability, and customization options. Whether for manufacturing, construction, or automotive applications, high-quality steel castings ensure long-term performance under demanding conditions.

1. High-Strength Alloy Steel Tray Castings: Built for Heavy-Duty Performance

High-strength alloy steel tray castings are engineered to withstand extreme loads, impacts, and harsh environments. These castings typically include elements like chromium, nickel, and molybdenum for enhanced tensile strength.

Key Benefits:

Tensile strength: ≥ 850 MPa (compared to 400-600 MPa for standard carbon steel).

Superior wear resistance, reducing replacement frequency.

Ideal for mining, aerospace, and heavy machinery applications.

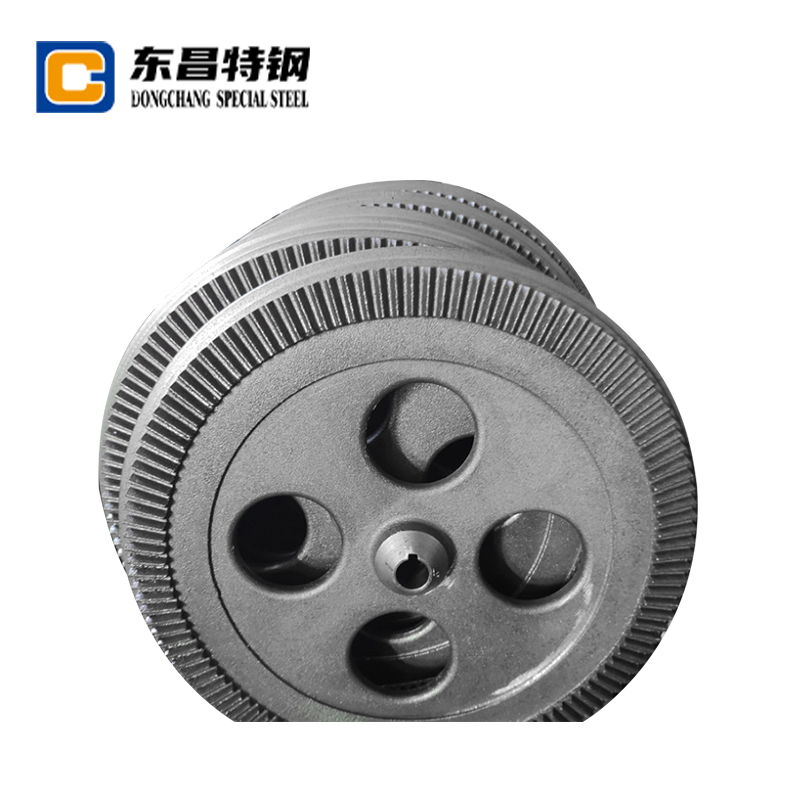

2. Custom Alloy Steel Casting Trays: Tailored for Precision Requirements

Custom alloy steel casting trays are designed to meet specific industry needs, including unique shapes, sizes, and load-bearing capacities.

Common Customization Options:

Dimensional adjustments (thickness, length, and reinforcement ribs).

Surface treatments (heat treatment, galvanization, or powder coating).

Compliance with industry standards (ASTM, DIN, or ISO certifications).

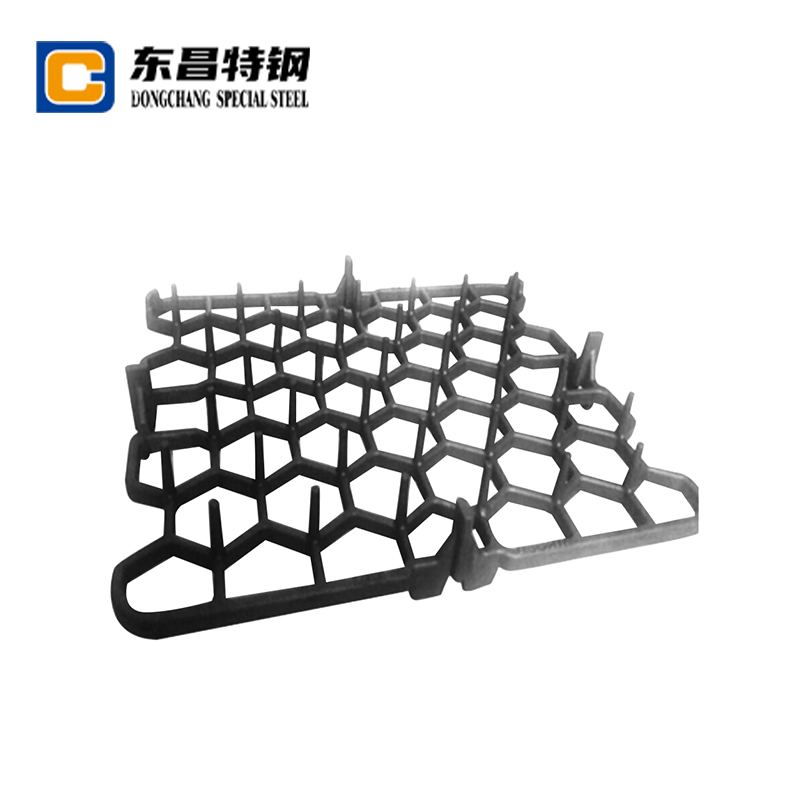

3. Durable Steel Material Casting Trays: Longevity in Harsh Conditions

Durability is a critical factor in industrial tray castings, ensuring minimal maintenance and extended service life.

Performance Comparison:

| Material | Average Lifespan | Corrosion Resistance |

|---|---|---|

| Standard Carbon Steel | 5-8 years | Moderate |

| Alloy Steel | 10-15+ years | High (with coatings) |

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878