Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

In the demanding world of high-temperature industrial applications, from next-generation ultra-fast charging hubs to aerospace propulsion systems, the integrity of the entire structure often hinges on a single, critical component: the frame. These are not ordinary frames; they are precision-engineered heat resistant steel material frame castings designed to withstand immense thermal and mechanical stress. This article delves into the science, selection, and application of these vital components, exploring how they maximize performance, ensure safety, and extend service life in the most extreme environments imaginable.

Understanding Heat Resistant Steel: The Foundation of Durability

Heat resistant steels are a specialized class of alloys engineered to maintain their structural integrity, resist oxidation (scaling), and resist creep deformation when exposed to temperatures exceeding 500°C (932°F). Unlike standard carbon steels, which rapidly lose strength at high temperatures, these alloys incorporate specific elements that create a stable microstructure even under thermal duress. The choice of material is the most fundamental decision in creating a reliable heat resistant steel material frame casting.

- Chromium (Cr): The cornerstone of heat resistance. Chromium forms a tight, adherent layer of chromium oxide (Cr₂O₃) on the surface, protecting the underlying metal from further oxidation and corrosion.

- Nickel (Ni): Stabilizes the austenitic microstructure, providing excellent toughness, ductility, and resistance to creep and thermal fatigue.

- Molybdenum (Mo) & Tungsten (W): Enhance strength at high temperatures by solid solution strengthening, improving resistance to creep.

- Niobium (Nb) & Titanium (Ti): Form stable carbides, preventing the detrimental formation of chromium carbides and subsequent sensitization, which can lead to intergranular corrosion.

Common Grades of Heat Resistant Steel for Castings

Selecting the right grade is a balance between temperature requirements, mechanical load, environmental conditions, and cost. Here are some of the most prevalent grades used for heavy-duty frame castings.

| Grade (Common Designation) | Key Characteristics | Typical Application Temperature Range |

| HK (25Cr-20Ni) | Excellent oxidation resistance and strength at high temperatures. A workhorse for many industrial applications. | Up to 1150°C (2100°F) |

| HP (25Cr-35Ni) | Higher nickel content provides superior carburization resistance and creep strength. Ideal for chemically harsh environments. | Up to 1150°C (2100°F) |

| 304H / 316H (Austenitic) | Good general-purpose resistance to oxidation and corrosion. Often used where temperatures are high but not extreme. | Up to 900°C (1650°F) |

| Alloy 800H | Excellent strength and resistance to oxidation, carburization, and sulfidation. A premium choice for critical applications. | Up to 1100°C (2000°F) |

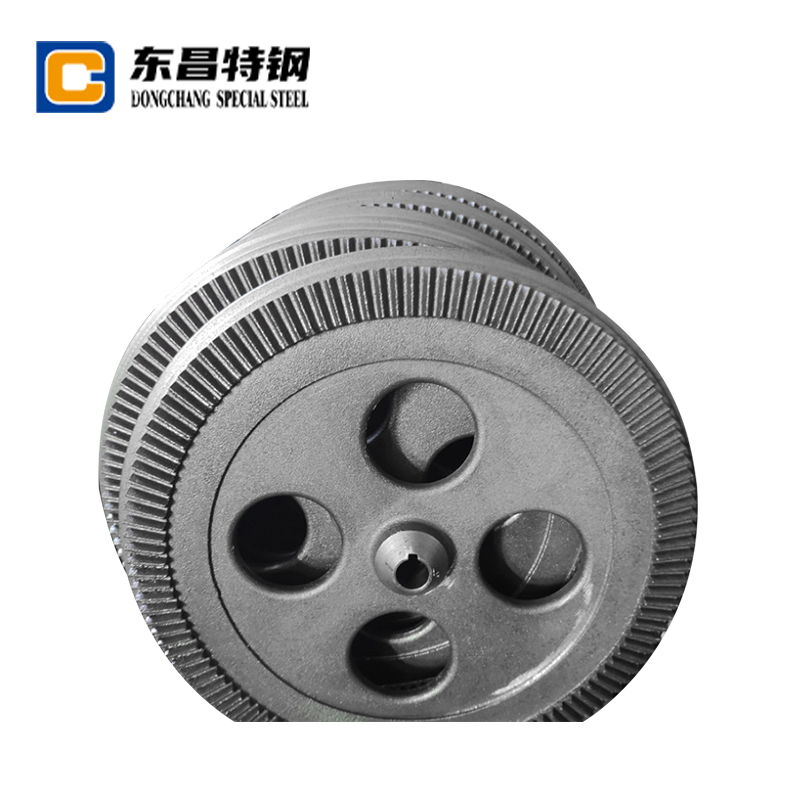

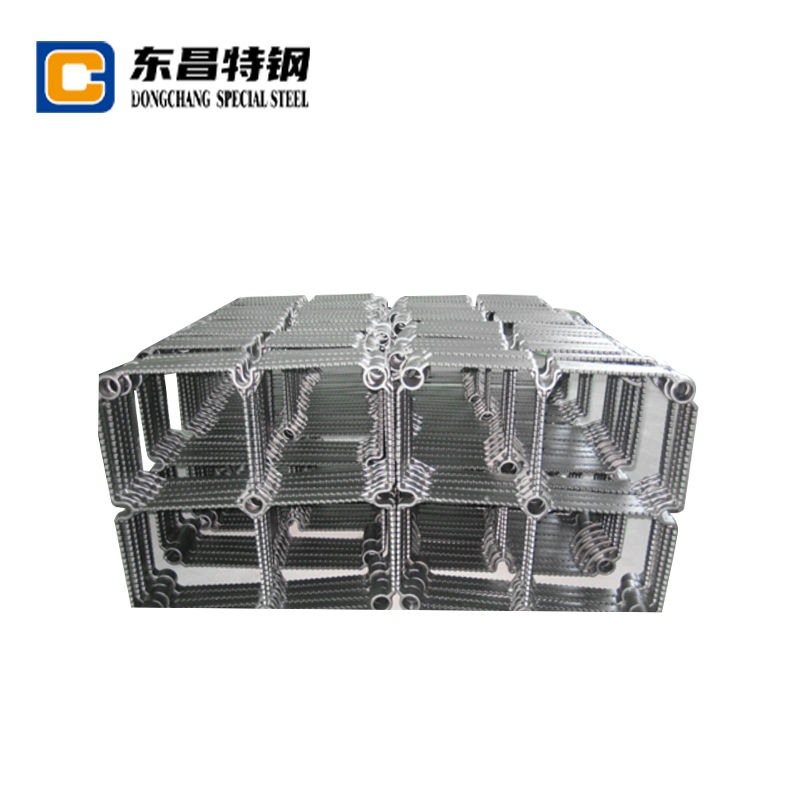

The Casting Process: Shaping Resilience for Demanding Applications

The manufacturing process is as critical as the material itself. Heat resistant steel casting processes for frames are chosen to achieve the complex geometries, dimensional accuracy, and sound internal structure required to handle extreme loads. The process must minimize defects like porosity and shrinkage, which can become failure points under stress.

- Investment Casting (Lost-Wax): Ideal for complex, near-net-shape frames with excellent surface finish and dimensional accuracy. This process is often preferred for intricate designs where machining should be minimized.

- Sand Casting: The most common method for large, heavy-section heat resistant steel material frame castings. It is cost-effective for low to medium volume production and can produce components weighing several tons.

- Shell Molding: Offers a good compromise between sand and investment casting, providing better dimensional accuracy and surface finish than conventional sand casting.

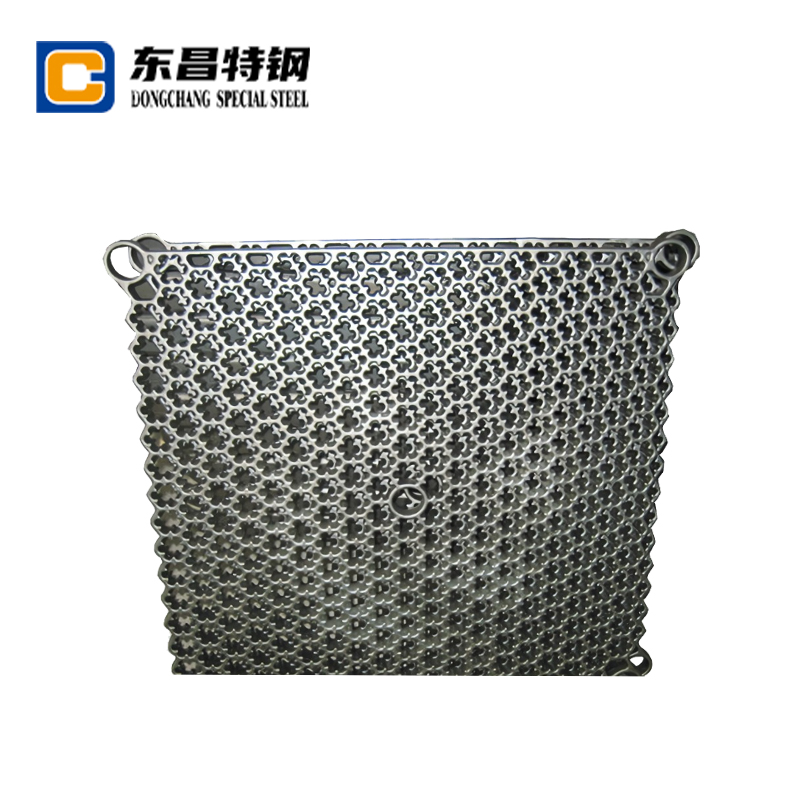

Why Choose Casting Over Fabrication?

For frame components in ultra-high-temperature environments, a monolithic casting often outperforms a welded fabrication.

- Design Freedom: Castings allow for optimized organic shapes that distribute stress evenly, something difficult to achieve with plates and welds.

- No Weld Decay: Eliminates the Heat-Affected Zone (HAZ) around welds, which can be a weak point susceptible to oxidation, creep, and cracking in service.

- Material Homogeneity: A properly made casting has a uniform microstructure throughout, ensuring consistent properties in every section of the frame.

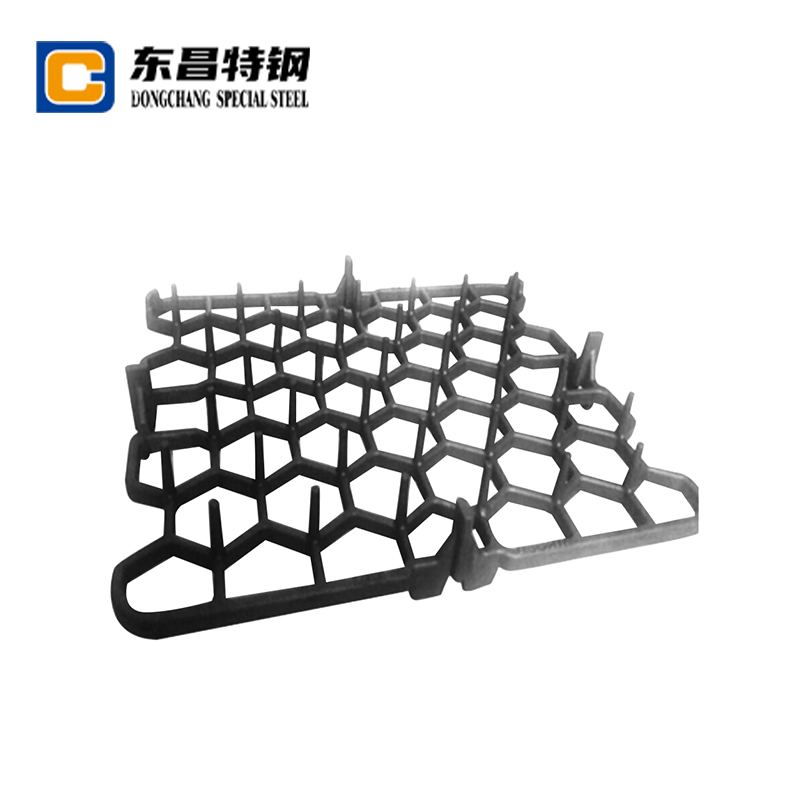

Key Applications: Where Heat Resistant Frame Castings Are Indispensable

The unique properties of these components make them essential in industries where failure is not an option. The pursuit of improving service life of heat resistant frames drives continuous innovation in these fields.

- Next-Gen Ultra-Fast Charging (UFC) Hubs: The core power electronics and cable management systems generate immense heat. Massive heat resistant steel material frame castings form the structural foundation, housing and protecting sensitive components while managing thermal expansion and ensuring alignment.

- Industrial Furnaces & Heat Treatment Equipment: Used for radiant tubes, furnace muffles, trays, and the structural framework itself. They withstand continuous thermal cycling and direct flame impingement.

- Power Generation: In gas turbines, boilers, and waste-to-energy plants, these castings are used for turbine housings, burner components, and support structures exposed to high-temperature exhaust gases.

- Petrochemical & Refining: Critical for reactor support grids, tube hangers, and piping components in reformers and crackers, where they resist high temperatures and corrosive atmospheres.

- Aerospace & Defense: Found in jet engine nacelles, afterburner components, and rocket motor supports, where high strength-to-weight ratio and reliability are paramount.

Design and Selection: A Guide for Engineers

Selecting the right heat resistant steel material frame casting is a multidisciplinary effort involving mechanical, materials, and design engineers. It's not just about picking a grade from a chart; it's about a holistic understanding of the application's demands. This is where a clear heat resistant frame material selection guide becomes invaluable.

- Mechanical Loads: Analyze static, dynamic, and cyclic loads (including thermal fatigue). Finite Element Analysis (FEA) is crucial for predicting stress concentrations.

- Thermal Profile: Define the maximum operating temperature, temperature gradients, heating/cooling rates (thermal shock), and the frequency of thermal cycles.

- Atmospheric Conditions: Identify potential corrodents: oxidizing, carburizing, sulfidizing, or chlorinating environments. This is often the deciding factor in material choice.

- Dimensional Stability: Consider the effects of thermal expansion over the operating range. Designs must allow for movement without inducing high stress.

Cost vs. Performance Analysis

While premium alloys like HP or Alloy 800H offer superior performance, their cost is significantly higher. The analysis must consider the total cost of ownership, not just the initial purchase price.

| Factor | Standard Grade (e.g., 304H) | High-Performance Grade (e.g., HP) |

| Initial Material Cost | Lower | Significantly Higher |

| Expected Service Life | Shorter, may require more frequent replacement | Longer, reduced downtime |

| Resistance to Failure | Higher risk of oxidation, creep, or corrosion failure | Lower risk, increased safety and reliability |

| Total Cost of Ownership | Potentially higher over 5-10 years | Often lower due to extended lifespan and reliability |

Maintenance and Lifespan Extension Strategies

Even the best-designed casting requires proper care. Maintenance tips for high temperature steel frames focus on monitoring and mitigating degradation mechanisms to prevent catastrophic failure and extend service intervals.

- Regular Visual Inspection: Look for signs of oxidation (scaling), distortion (sagging or warping), and surface cracks. Thermal imaging cameras can identify hot spots indicating internal issues.

- Non-Destructive Testing (NDT): Implement scheduled NDT like ultrasonic testing (UT) to check for internal voids or cracks and dye penetrant inspection (DPI) to find surface-breaking cracks.

- Control Atmosphere Chemistry: In furnace applications, maintaining a consistent and designed-for atmosphere can drastically slow down corrosion and carburization processes.

- Avoid Thermal Shock: Adhere to prescribed heating and cooling rates. Rapid temperature changes can cause thermal stress cracking, especially in older components that have undergone microstructural changes.

FAQ

What is the maximum continuous operating temperature for heat resistant steel castings?

The maximum temperature varies significantly by alloy composition. Standard austenitic grades like 304H can typically operate continuously up to around 870°C (1600°F). High-performance cast grades like HK (25/20) and HP (25/35) are designed for continuous service at temperatures up to 1150°C (2100°F). It's crucial to note that the applied mechanical load dramatically affects the maximum usable temperature; a higher load lowers the effective temperature limit due to creep.

How does thermal cycling affect the lifespan of a heat resistant frame casting?

Thermal cycling is one of the most damaging operational modes. Each heat-up and cool-down cycle induces stresses due to differential thermal expansion. Over time, this leads to thermal fatigue, which manifests as a network of cracks on the surface and eventually throughout the structure. Components subjected to frequent cycling will have a shorter lifespan than those operating at a steady state temperature, even if the peak temperature is lower. Design strategies to mitigate this include using alloys with high thermal fatigue resistance and designing geometries to minimize stress concentrations.

Can a cracked heat resistant steel casting be repaired, or does it need replacement?

Repair is often possible but highly specialized. The most common method is welding repair. However, welding heat-resistant castings is challenging due to their high alloy content and susceptibility to cracking during the welding process. It requires: * **Precise Pre-heating:** The entire component must be heated to a specific temperature (often several hundred degrees Celsius) to avoid thermal shock. * **Specialized Filler Metals:** The weld rod must match or exceed the base metal's composition and properties. * **Strict Interpass Temperature Control:** The temperature must be carefully maintained between weld passes. * **Controlled Post-Weld Heat Treatment (PWHT):** A stress relief cycle is almost always mandatory. For critical applications, replacement is often the safer and more economical long-term choice versus a complex repair.

What is the difference between heat resistant and refractory steels?

While the terms are sometimes used interchangeably, there's a key distinction: * **Heat Resistant Steels:** These are metallic alloys (primarily iron-based with Cr, Ni, etc.) that are designed to retain high mechanical strength and resist oxidation at elevated temperatures. They are still structural metals. * **Refractories:** These are non-metallic, ceramic-based materials (e.g., alumina, silica, fireclay, zirconia) with very high melting points. They excel in extreme temperatures (often > 1500°C / 2700°F) but are typically brittle and have low tensile strength. They are used as linings (insulation) to protect the structural steel frame from the highest temperatures. In many applications, a heat resistant steel material frame casting provides the structural support, while a refractory lining protects it from direct flame contact.

How do I choose between a casting and a fabricated/welded frame for a high-temperature application?

The choice hinges on temperature, complexity, and required reliability. * **Choose a Casting For:** The most severe environments (high thermal cycles, corrosive atmospheres), complex geometries that optimize stress flow, and applications where weld failure is a critical risk. Castings provide a homogeneous structure with no weld-induced weak points. * **Consider Fabrication For:** Lower temperature applications (generally below 650°C / 1200°F), simpler geometries, large one-off structures where tooling for a casting would be prohibitively expensive, or when lead time for a casting is too long. Fabricated frames require meticulous welding procedures using compatible filler metals and full PWHT.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878