Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

Heat resistant steel material frame castings are critical components in industries where extreme temperatures are the norm. From industrial furnaces to power generation plants, these castings must withstand immense heat without losing their structural integrity. But what exactly makes a steel casting "heat resistant"? And how do you choose the right material for your specific application? This article will dive deep into the world of heat resistant castings, providing an in-depth look at material selection, applications, and performance factors to help you make informed decisions.

We'll explore key considerations for anyone working with these specialized materials, including specific alloys and their unique properties, and address common questions about their performance and lifespan. Whether you're a design engineer or a maintenance professional, this guide will serve as a valuable resource.

Choosing the Right Alloy for Your Application

Selecting the right alloy is the first and most critical step. The choice depends on the specific temperature range and the operating environment. The primary alloying elements that give steel its heat resistance are chromium and nickel. Chromium provides oxidation resistance, while nickel improves high-temperature strength and thermal stability. Other elements like silicon and aluminum also play a role in improving resistance to specific environmental attacks.

Let's look at a few common alloys used in heat resistant steel material frame castings and their typical applications. We will compare their properties to help you understand their differences and find the best fit for your needs. This comparison will help you answer questions like, what is the best heat resistant steel casting alloy?

| Alloy Grade | Nominal Composition (Cr/Ni) | Maximum Service Temperature | Typical Applications |

| HK40 | 25% Cr, 20% Ni | Up to 1,150°C (2,100°F) | Furnace rollers, radiant tubes, and conveyor parts in high-temperature environments. |

| HP50W | 26% Cr, 35% Ni, 1.25% Nb | Up to 1,200°C (2,200°F) | Ethylene pyrolysis coils, reformer tubes, and other components requiring exceptional creep strength. |

| HH | 25% Cr, 12% Ni | Up to 1,100°C (2,000°F) | Furnace grates, dampers, and general-purpose furnace hardware. |

Applications of Heat Resistant Castings

The applications for heat resistant castings are diverse and demanding, spanning multiple industries. Their ability to maintain strength and shape under extreme thermal stress makes them indispensable. Below are some of the key sectors where these castings are utilized.

Power Generation

In power plants, components operate under constant high heat and pressure. Heat resistant steel castings for power plant applications are crucial for components such as boiler hangers, supports, and grates, where failure could lead to significant downtime and safety risks.

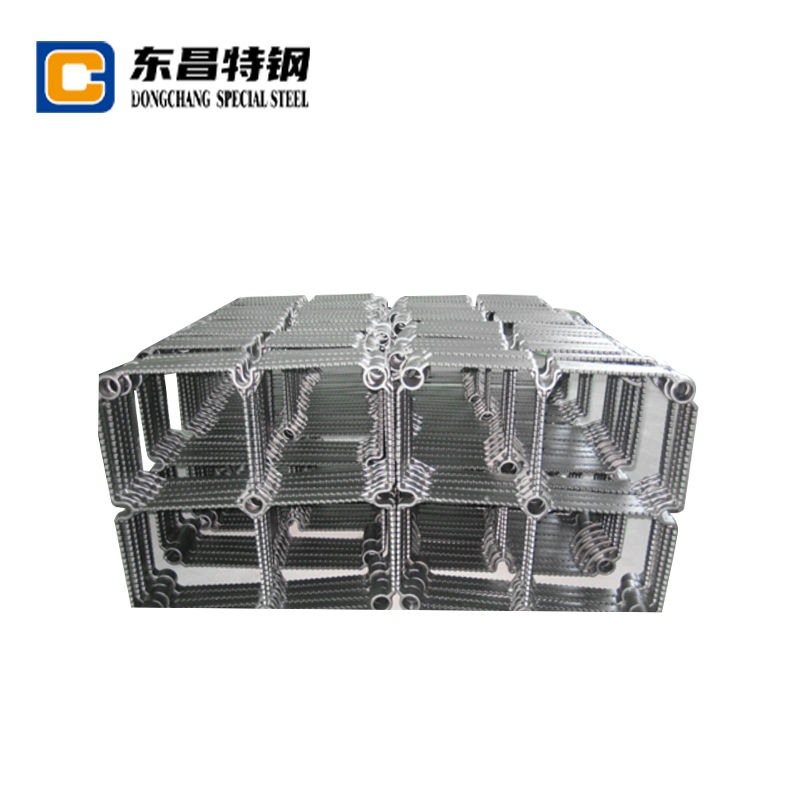

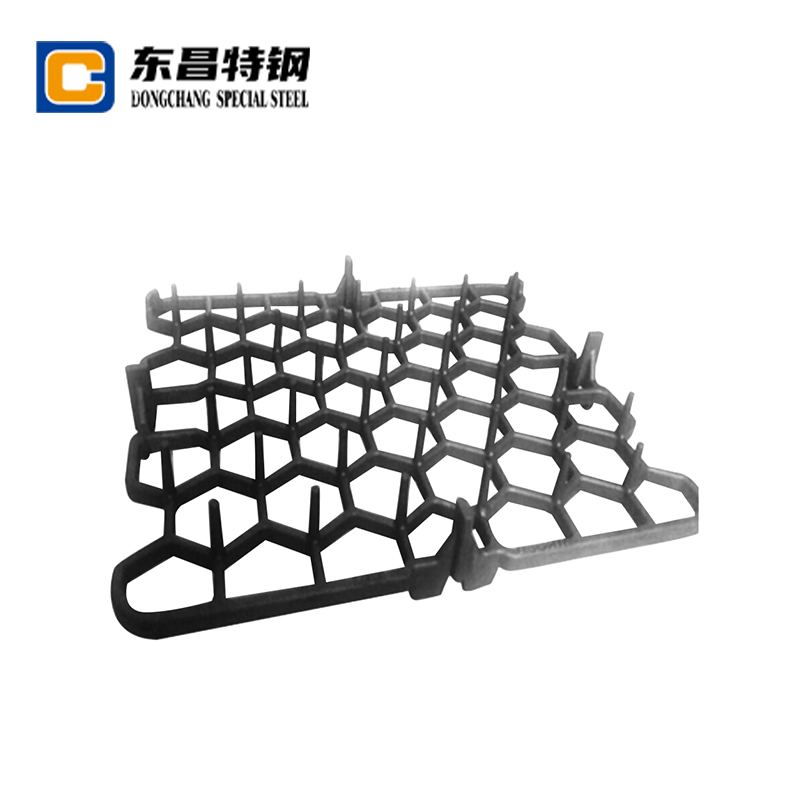

Industrial Furnaces and Kilns

Industrial furnaces and kilns are the workhorses of many manufacturing processes. The internal components, such as burners, dampers, and rollers, must withstand continuous high temperatures. The use of robust castings for high temperature furnace components ensures a longer lifespan and reduced maintenance costs.

Cement and Mining

The rotary kilns in cement production and mining equipment often involve extreme temperatures and abrasive conditions. Heat resistant castings provide the durability needed to withstand this harsh environment, ensuring operational efficiency and longevity.

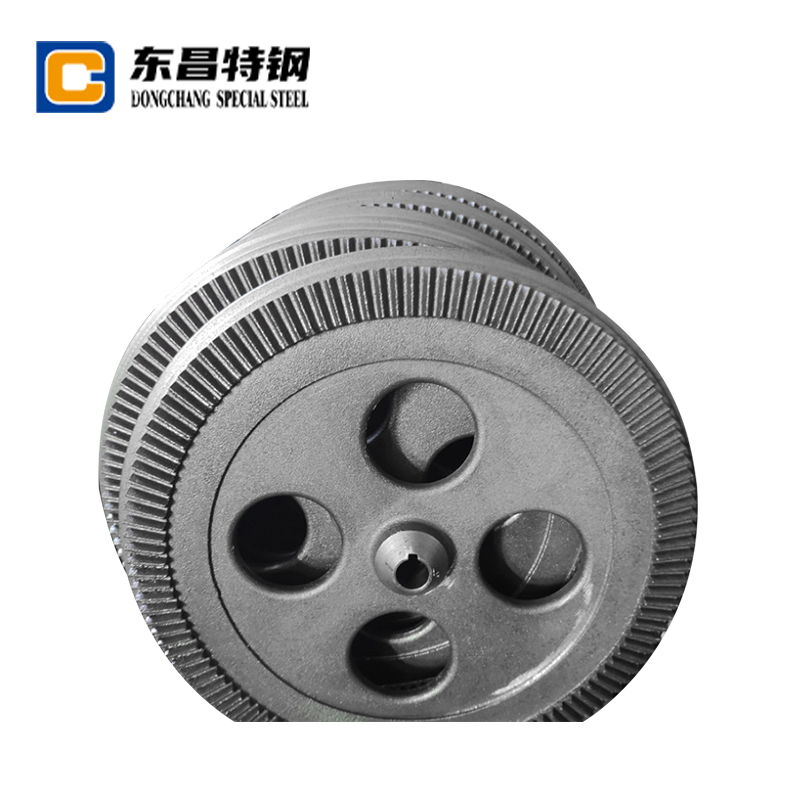

Steel Manufacturing and Heat Treatment

Steel mills use a variety of heat treatment processes that require reliable equipment. Components like walking beams, skid rails, and annealing furnace parts are commonly made from high temperature cast steel to endure repeated thermal cycles without fatigue or failure.

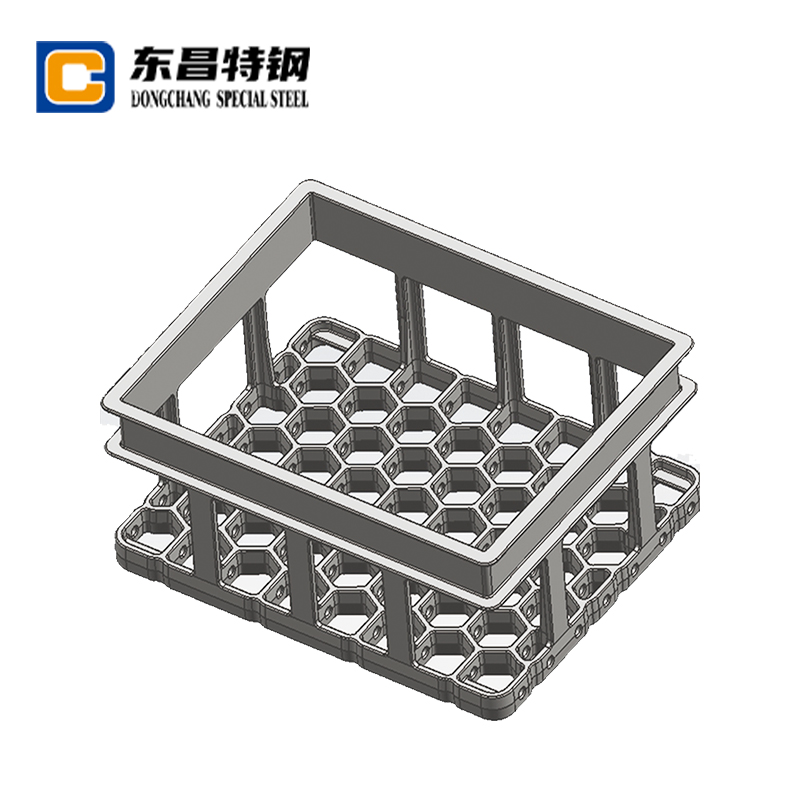

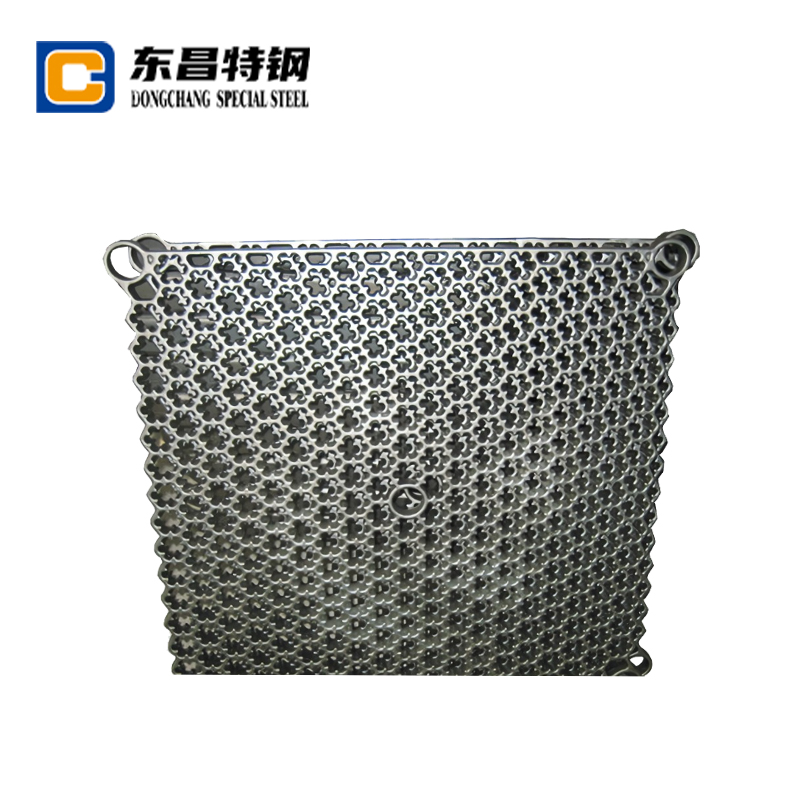

Industrial Furnace Material Basket Castings

Factors Influencing Performance and Lifespan

The performance and longevity of heat resistant steel material frame castings are not just about the alloy; they also depend on a variety of operational and design factors. Understanding these elements can help maximize the lifespan of your components and optimize performance.

Design Considerations

Proper design is crucial. Components should be designed to minimize thermal stress and allow for controlled expansion and contraction. For instance, sharp corners and sudden changes in cross-section can create stress points that lead to cracking. A well-designed casting, therefore, is just as important as the material itself.

Environmental Conditions

The specific atmosphere of the application—whether it's oxidizing, reducing, or carburizing—significantly affects the material's performance. For example, a casting used in a carburizing environment, which introduces carbon into the steel, might require an alloy with higher nickel content to resist embrittlement.

For a clear comparison of how different environmental conditions affect heat resistant steel, refer to the table below.

| Environment | Primary Threat | Material Recommendation |

| Oxidizing | Scaling and surface degradation | High chromium alloys (e.g., HK40) to form a stable oxide layer. |

| Carburizing | Embrittlement and cracking | Higher nickel alloys (e.g., HP50W) for improved resistance. |

| Sulfidation | Intergranular attack | Higher chromium and silicon content to resist sulfur attack. |

Maintenance and Inspection

Regular inspection and maintenance are vital for extending the lifespan of heat resistant castings. Look for signs of surface cracking, scaling, or deformation. Early detection of these issues can prevent catastrophic failure and allow for timely replacement. Proper maintenance schedules are particularly important in applications with significant thermal cycling.

For more detailed information on specific alloys and their resistance to environmental factors, consulting with a metallurgist or a materials specialist is highly recommended. For those looking for specialized solutions, custom heat resistant steel casting manufacturers can provide tailored products designed for unique applications.

Summary

In summary, heat resistant steel material frame castings are indispensable components in high-temperature industrial environments. Choosing the right alloy, like HP50W for exceptional creep strength or HK40 for general purpose applications, is paramount. These castings are used in critical applications across power generation, industrial furnaces, and other demanding sectors. Their performance and lifespan are influenced by factors like design, environmental conditions, and maintenance practices. By understanding these elements, you can ensure the reliability and longevity of your high-temperature components. For more information or specialized solutions, consider reaching out to a company that specializes in custom heat resistant steel casting manufacturers to meet your specific needs.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878