Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

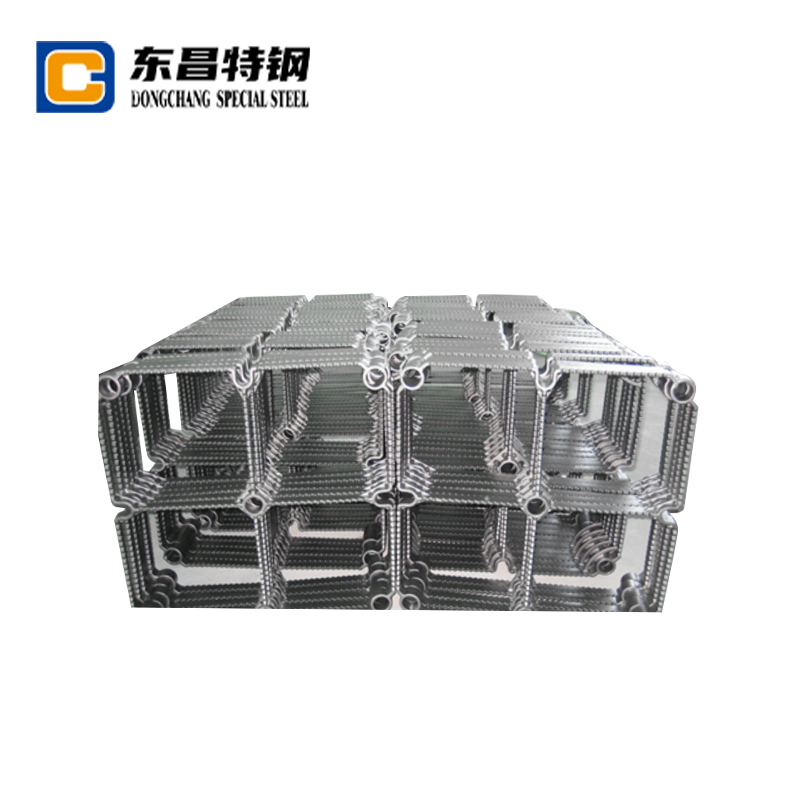

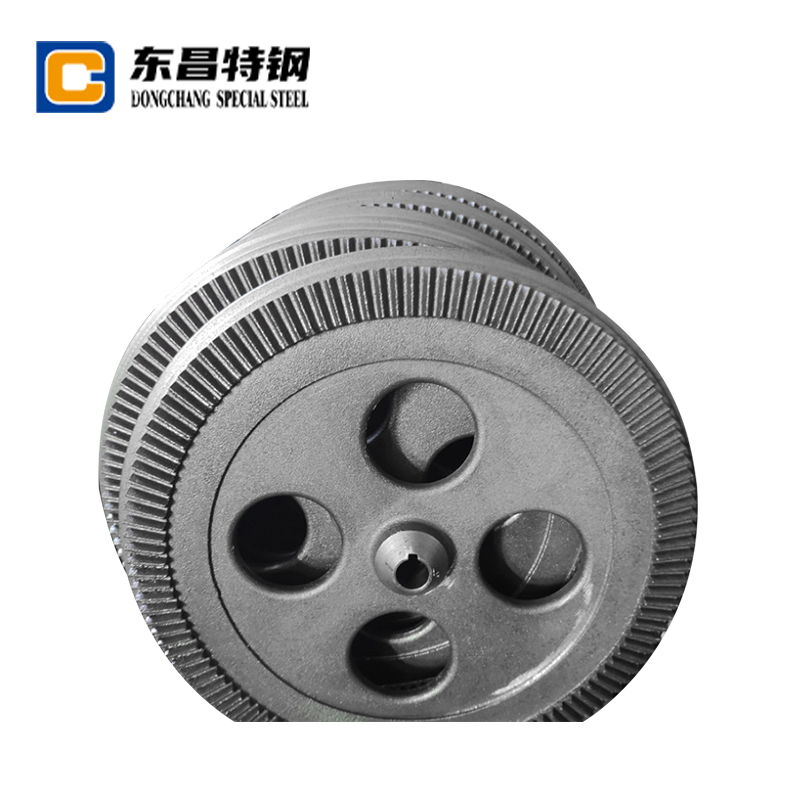

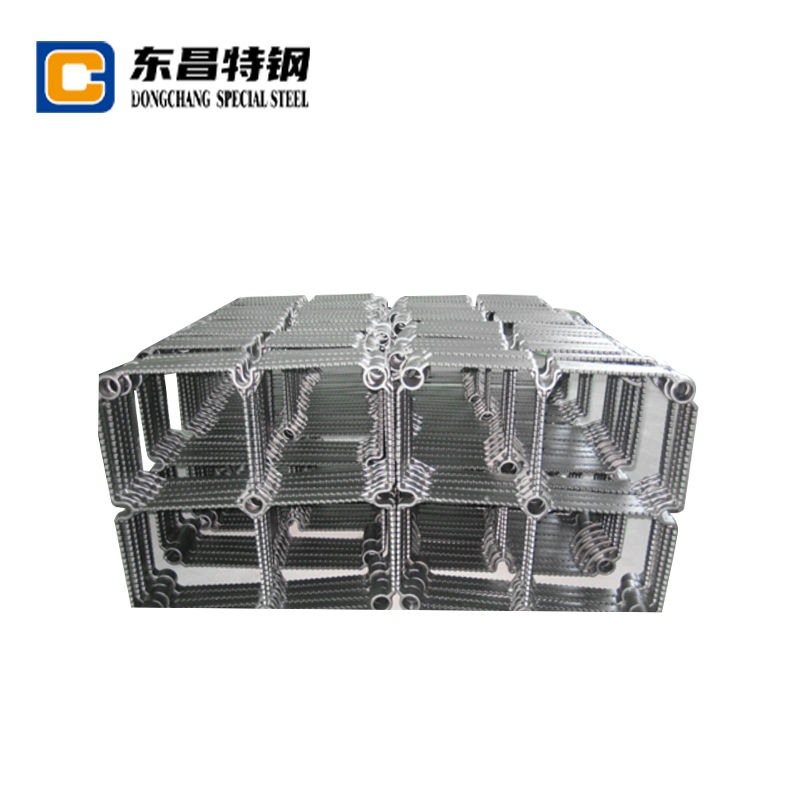

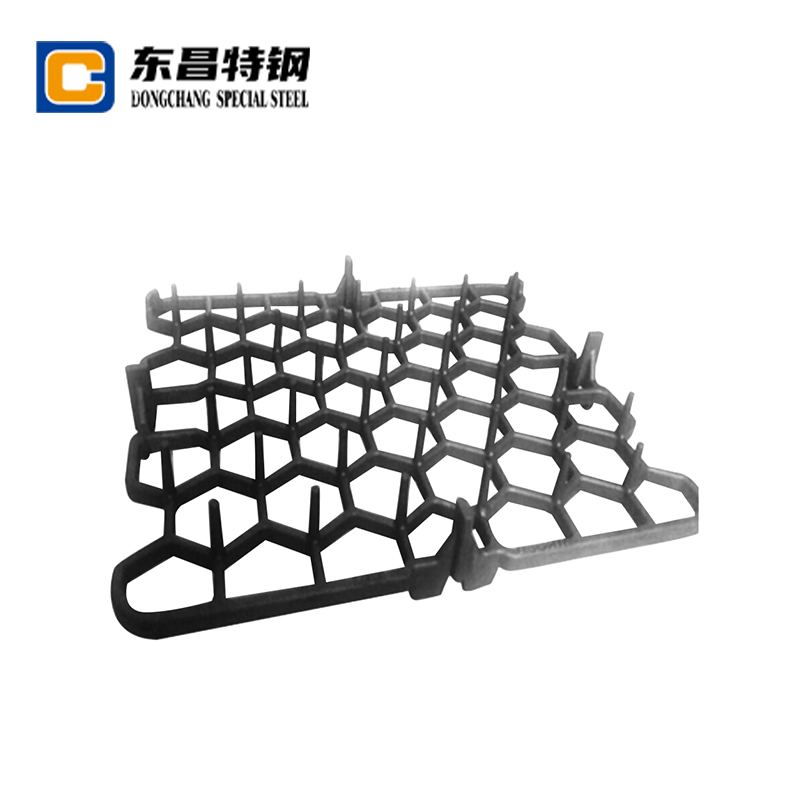

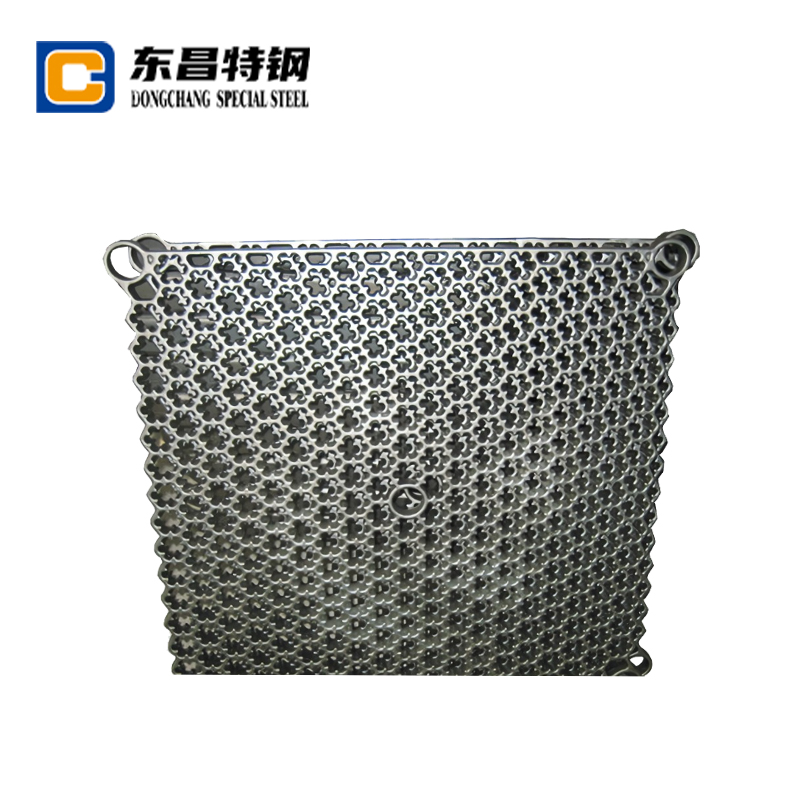

Alloy steel material tray castings play a critical role in industrial applications, especially under high temperature, high pressure, and heavy-load conditions. Their performance directly affects operational efficiency and safety. By selecting appropriate alloying elements, the heat resistance, oxidation resistance, and high-temperature strength of the castings can be significantly enhanced to meet specific operational requirements.

Effects of Alloying Elements on Alloy Steel Material Tray Castings Performance

During the manufacturing of alloy steel material tray castings, different alloying elements can be added to adjust properties according to application requirements. The following are common alloying elements and their effects:

- Chromium (Cr): Improves heat resistance and oxidation resistance, suitable for high-temperature environments.

- Nickel (Ni): Enhances corrosion resistance and toughness, ideal for harsh environments.

- Molybdenum (Mo): Increases high-temperature strength and creep resistance, suitable for high-load, high-temperature conditions.

Chromium (Cr) and Heat Resistance Enhancement

Chromium is essential for improving the heat resistance of alloy steel tray castings. It forms a stable oxide layer that reduces oxidation damage and extends service life.

Nickel (Ni) and Oxidation Resistance Improvement

Adding nickel improves oxidation resistance, especially in high-temperature oxidative environments. Nickel effectively suppresses oxidation reactions, maintaining the stability of the casting.

Molybdenum (Mo) and High-Temperature Strength

Molybdenum significantly enhances the high-temperature strength and creep resistance of alloy steel tray castings, making them suitable for high-load, high-temperature applications.

Heat Treatment Processes for Alloy Steel Material Tray Castings

Heat treatment is a key process to enhance the performance of alloy steel material tray castings. Controlling the heating and cooling process adjusts the microstructure to achieve desired properties.

- Annealing: Reduces hardness, improves ductility and toughness.

- Normalizing: Refines grain structure, improves strength and hardness.

- Quenching: Increases hardness and wear resistance.

- Tempering: Relieves quenching stress and enhances toughness.

Impact of Heat Treatment on Performance

Heat treatment significantly improves mechanical properties such as hardness, strength, and toughness, enabling alloy steel material tray castings to meet diverse operational requirements.

Common Heat Treatment Methods

Selecting the appropriate heat treatment method ensures the optimal performance of alloy steel tray castings based on application needs.

Applications of Alloy Steel Material Tray Castings

Alloy steel material tray castings are widely used in high-temperature, high-pressure, and heavy-load environments, such as heat treatment equipment, heavy machinery, and high-temperature furnaces.

- High-Temperature Applications: Used in heat treatment equipment trays requiring excellent heat and oxidation resistance.

- Heavy-Load Applications: Used in heavy machinery trays requiring high strength and toughness.

Conclusion: Comprehensive Impact of Alloying Elements on Alloy Steel Material Tray Castings

By carefully selecting alloying elements and heat treatment processes, the performance of alloy steel material tray castings can be significantly improved to meet specific operational needs. Practical applications require a comprehensive approach considering both alloy composition and heat treatment design.

FAQ

What are the main alloying elements in alloy steel tray castings?

The main alloying elements in alloy steel tray castings include Chromium (Cr), Nickel (Ni), Molybdenum (Mo), Manganese (Mn), and Silicon (Si). Each element provides unique properties, such as improved heat resistance, oxidation resistance, and high-temperature strength.

How to choose the right alloy steel tray castings?

Choosing the right alloy steel tray castings depends on operational environment and requirements, such as working temperature, load conditions, and corrosion environment. Consider alloying elements and heat treatment design for optimal performance.

What are common heat treatment methods for alloy steel tray castings?

Common heat treatment methods include annealing, normalizing, quenching, and tempering. Each method adjusts the microstructure of alloy steel tray castings to achieve desired mechanical properties.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878