Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

Exploring Alloy Steel Material Trays and Heat Treatment Cement Plant Grate Castings

In industrial environments where extreme temperatures and mechanical stress are common, heat-resistant steel material frame castings play a crucial role in ensuring structural integrity and longevity. These specialized castings are designed to withstand high temperatures, corrosion, and heavy loads, making them indispensable in industries such as cement plants, power generation, and metallurgy.

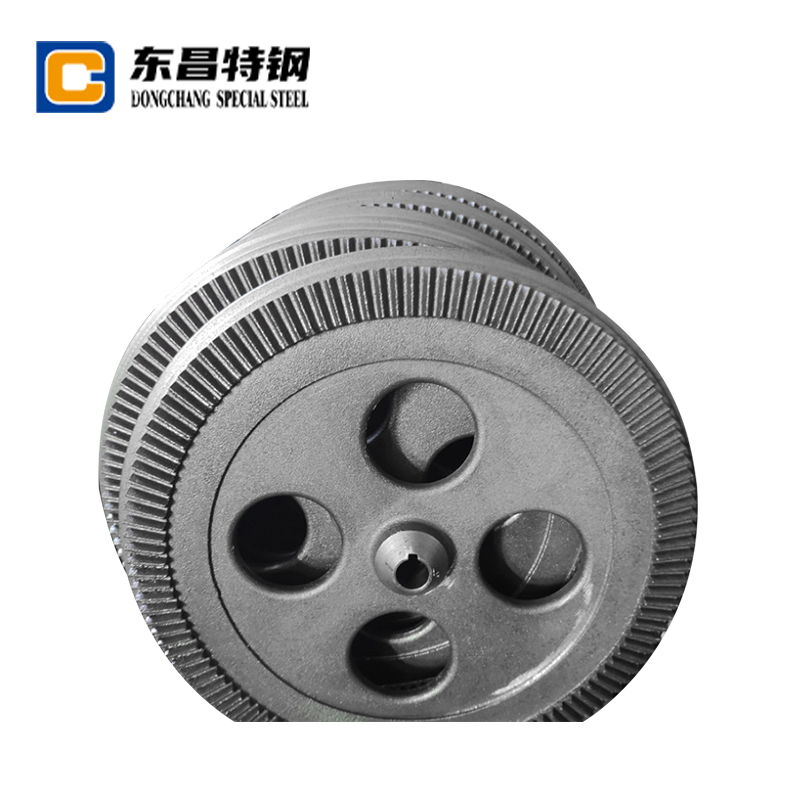

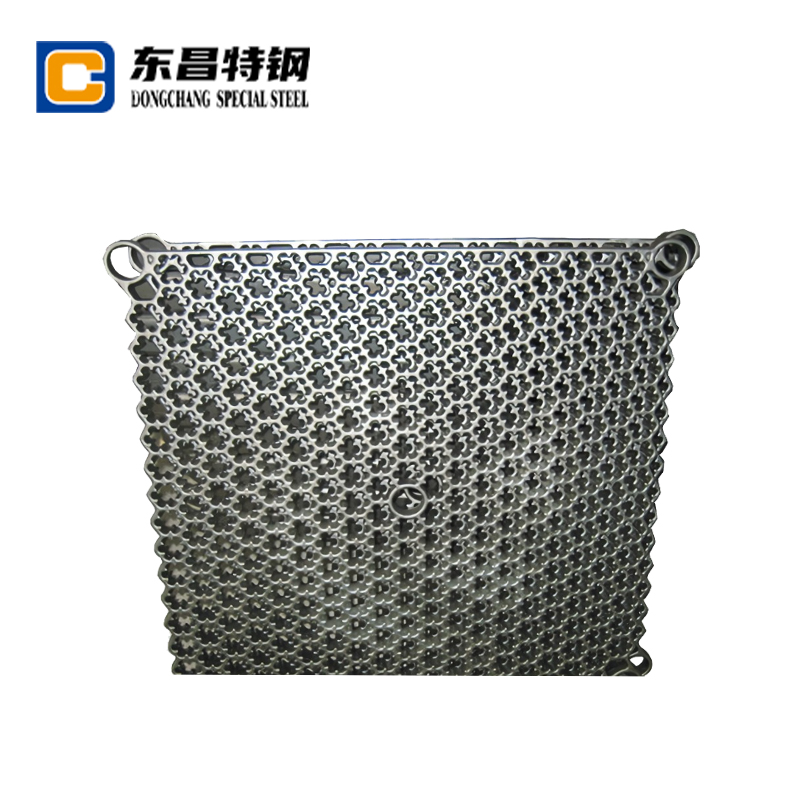

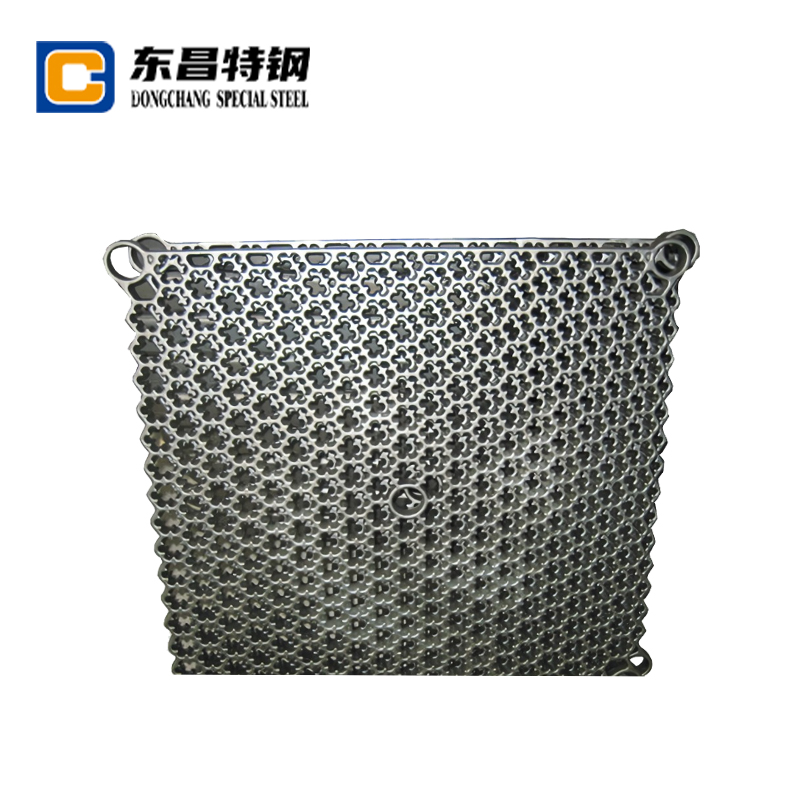

Heavy Duty Precision Casting Material Tray Castings

The Role of Heat-Resistant Steel Frame Castings

Heat-resistant steel frame castings are engineered to maintain strength and stability under extreme thermal conditions. Key features include:

High-Temperature Stability: Retains mechanical properties even at elevated temperatures.

Corrosion Resistance: Resists oxidation and chemical degradation.

Durability: Withstands thermal cycling and mechanical stress without deformation.

Applications

Cement Plants: Used in kiln supports, preheater towers, and cooler grates.

Power Generation: Essential for boiler supports and turbine housings.

Steel & Foundry Industries: Employed in furnace components and conveyor systems.

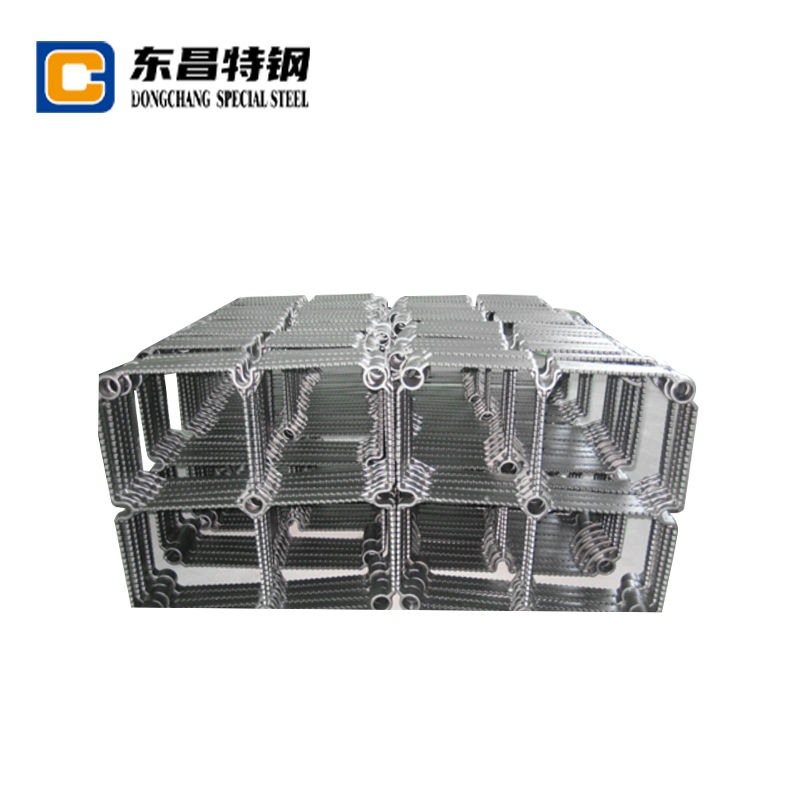

Alloy Steel Material Trays: Supporting High-Temperature Processes

Alloy steel trays complement heat-resistant frame castings by providing a stable platform for material handling in harsh environments. These trays are often used in:

Heat Treatment Furnaces: Holding components during quenching and tempering.

Industrial Ovens: Transporting materials through high-temperature zones.

Chemical Processing: Resisting corrosive substances while maintaining structural integrity.

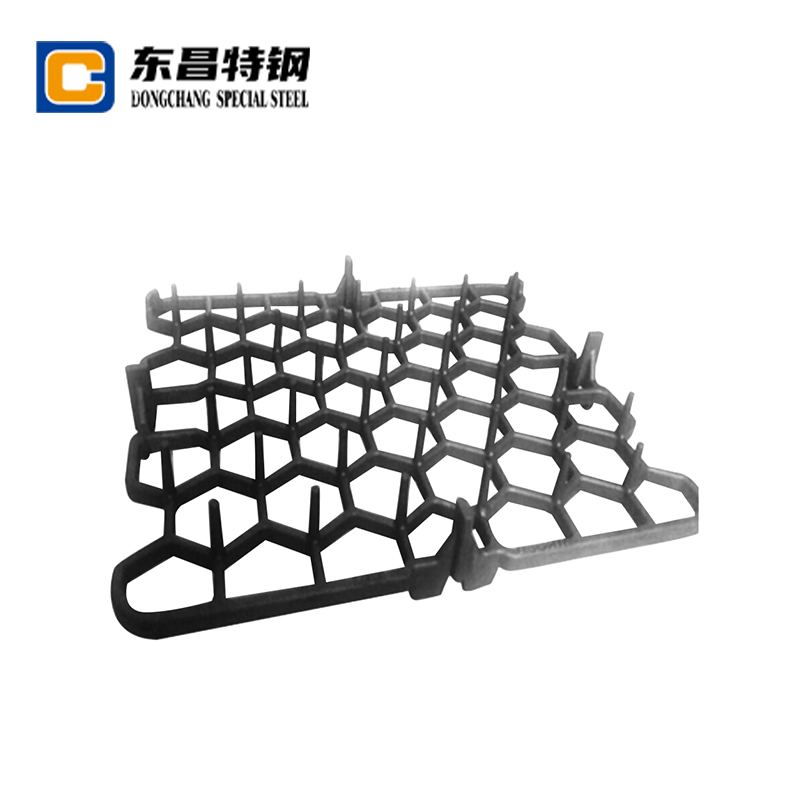

Heat Treatment Cement Plant Grate Castings: Ensuring Efficient Clinker Cooling

In cement manufacturing, grate castings are critical for cooling clinker efficiently. These castings must endure:

Thermal Shock: Rapid temperature changes during cooling.

Abrasion: Constant movement of clinker particles.

Mechanical Load: Heavy-duty operation in rotary coolers.

Heat-resistant materials like high-chromium steel or nickel alloys are commonly used to enhance durability.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878