Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

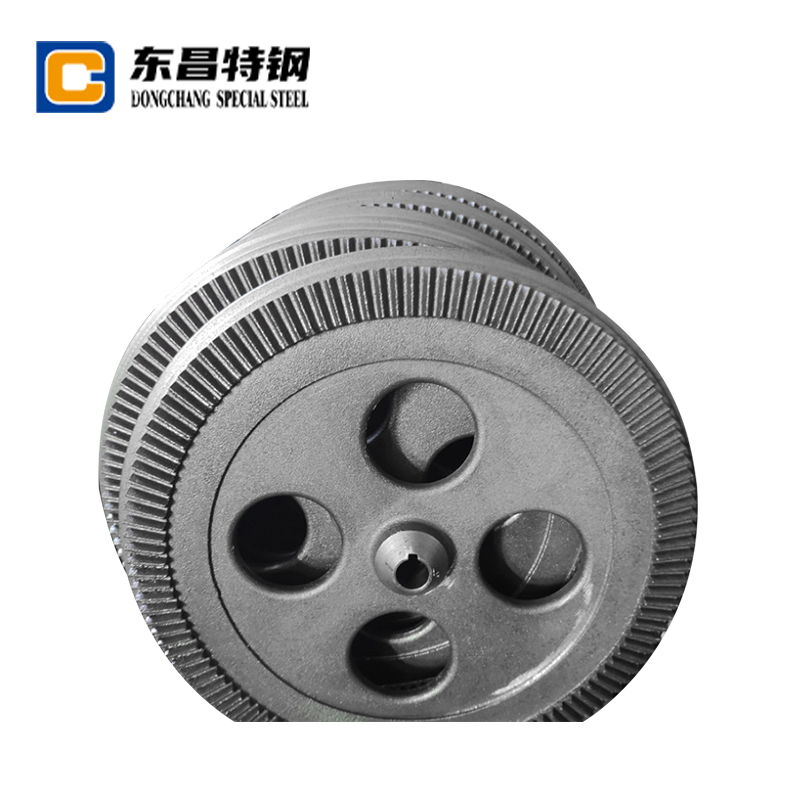

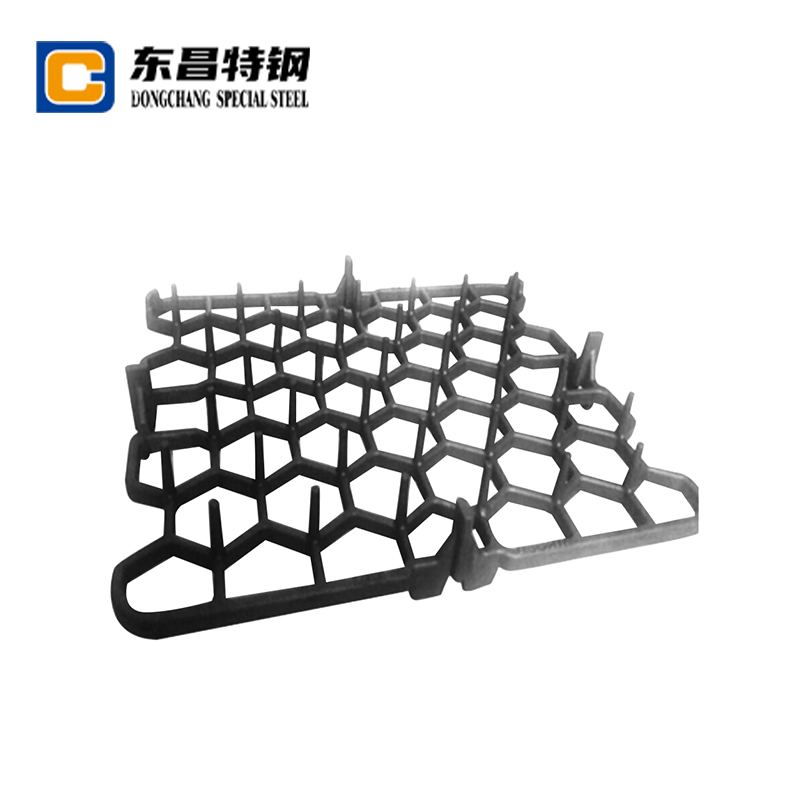

Metal alloy steel casting products are widely used in industries that demand high strength, wear resistance, and thermal stability. These castings are essential in sectors such as aerospace, automotive, energy, and heavy machinery. Among the most common applications are Alloy Steel Material Tray Castings and Heat Resistant Steel Material Frame Castings, both of which offer unique advantages in performance and longevity.

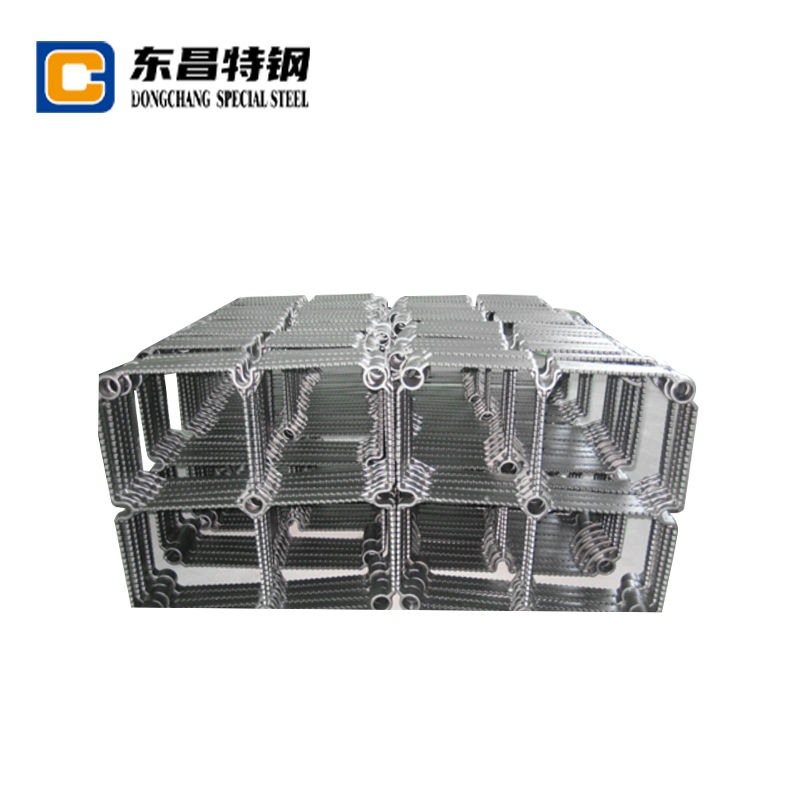

Heat Resistant Steel Loading Frame Castings

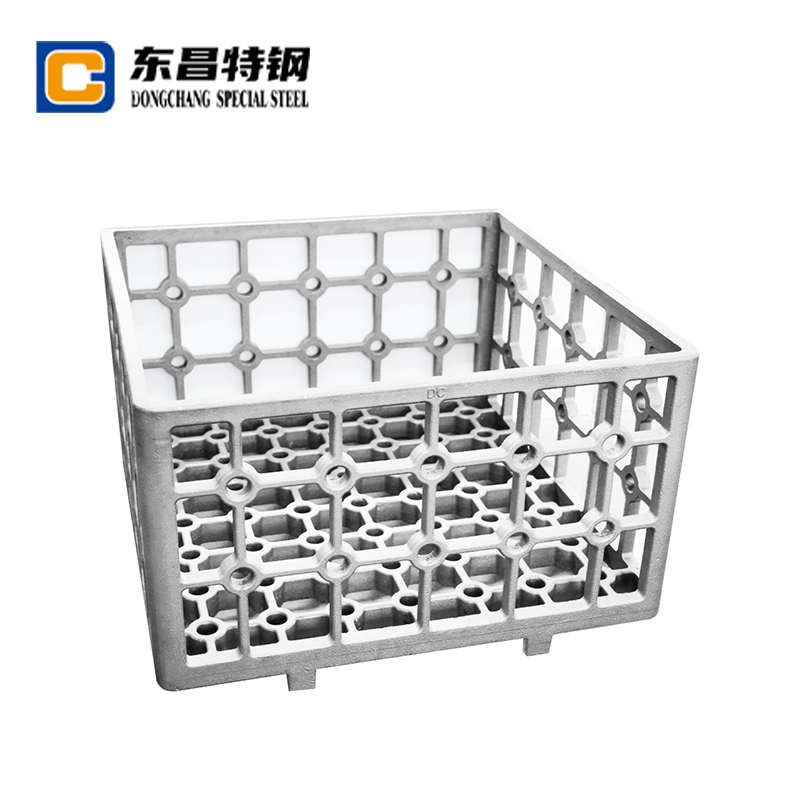

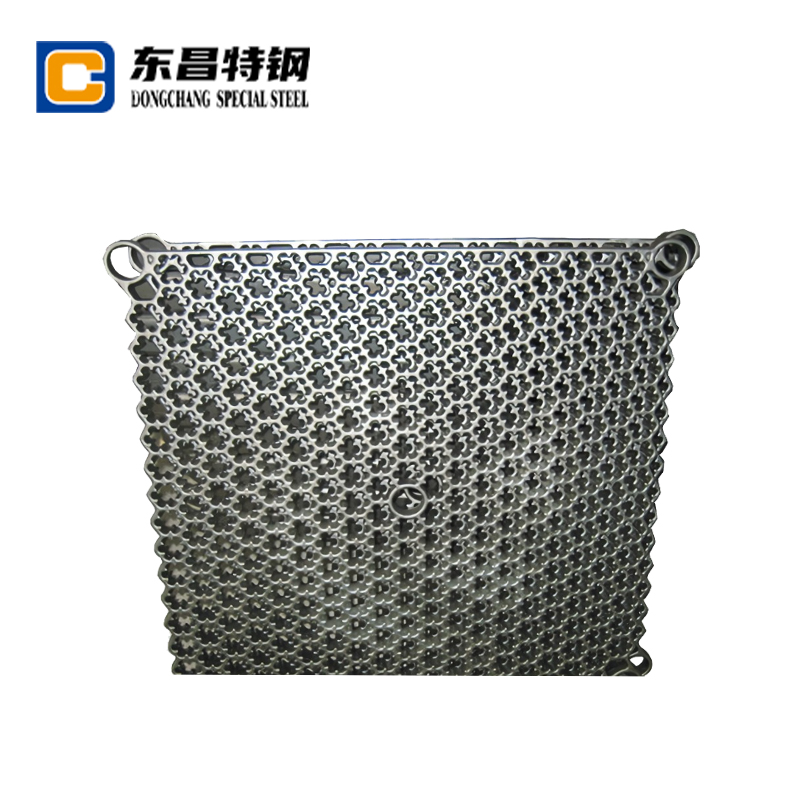

Alloy Steel Material Tray Castings: High Strength for Industrial Applications

Alloy steel tray castings are designed to withstand heavy loads and harsh working conditions. These castings typically incorporate elements such as chromium, nickel, and molybdenum to enhance mechanical properties.

Key Features:

High Tensile Strength: Alloy steel trays can endure stresses up to 850-1000 MPa, making them ideal for material handling.

Wear Resistance: The addition of alloying elements improves abrasion resistance, extending service life.

Corrosion Resistance: Chromium content (1-5%) provides moderate corrosion protection in demanding environments.

Comparison with Standard Carbon Steel Trays:

| Property | Alloy Steel Tray Castings | Carbon Steel Tray Castings |

|---|---|---|

| Tensile Strength | 850-1000 MPa | 400-550 MPa |

| Wear Resistance | Excellent | Moderate |

| Corrosion Resistance | Good (with Cr content) | Low |

These properties make alloy steel tray castings a preferred choice for mining, construction, and manufacturing industries.

Heat Resistant Steel Material Frame Castings: Stability Under Extreme Temperatures

Heat-resistant steel frame castings are engineered to maintain structural integrity in high-temperature environments, such as furnaces, power plants, and chemical processing units. These castings often include chromium, silicon, and nickel to resist oxidation and thermal fatigue.

Key Features:

Thermal Stability: Can operate continuously at temperatures up to 1100°C (2012°F) without significant deformation.

Oxidation Resistance: Forms a protective oxide layer, reducing material degradation.

Creep Resistance: Maintains strength under prolonged stress at elevated temperatures.

Comparison with Standard Alloy Steel Frames:

| Property | Heat-Resistant Steel Frames | Standard Alloy Steel Frames |

|---|---|---|

| Max Operating Temp | 1100°C | 600-700°C |

| Oxidation Resistance | Excellent | Moderate |

| Creep Resistance | High | Medium |

These characteristics make heat-resistant steel frame castings indispensable in industries where thermal endurance is critical.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878