Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

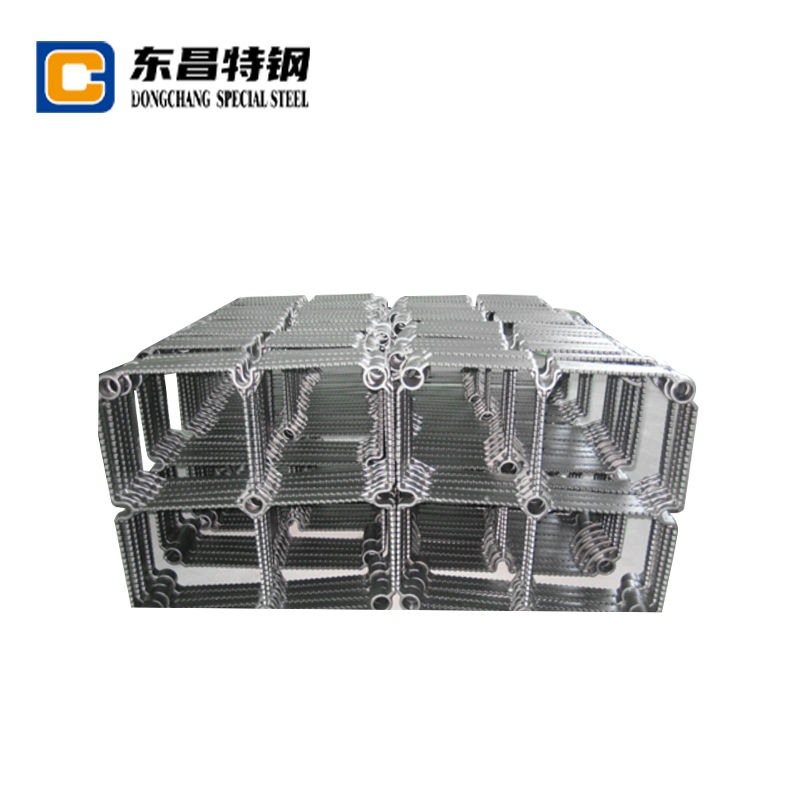

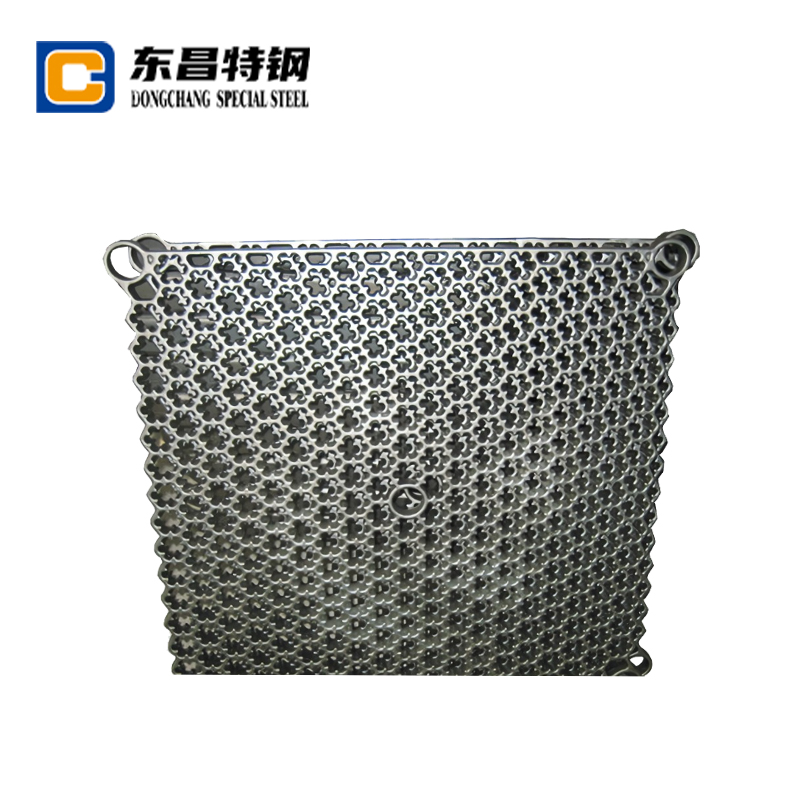

Industrial furnace spare parts castings play a critical role in maintaining the efficiency and longevity of high-temperature equipment. These components are designed to withstand extreme heat, mechanical stress, and corrosive environments, ensuring uninterrupted operations in industries such as steelmaking, glass manufacturing, and chemical processing.

Connecting Pipe, Heat Resistant And Wear-Resistant Thermocouple Tube Castings

What Are Industrial Furnace Spare Parts Castings?

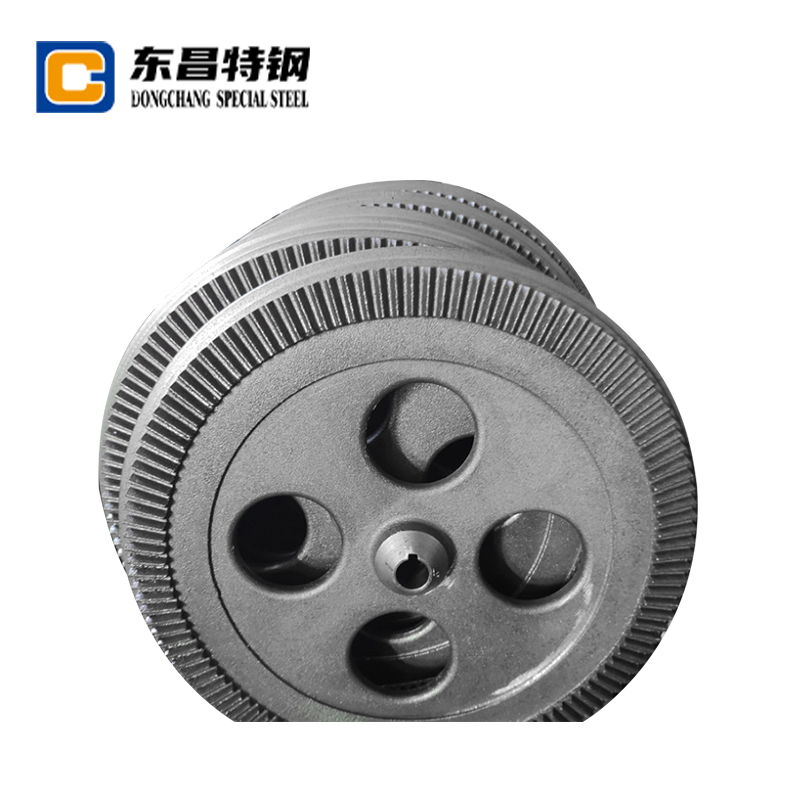

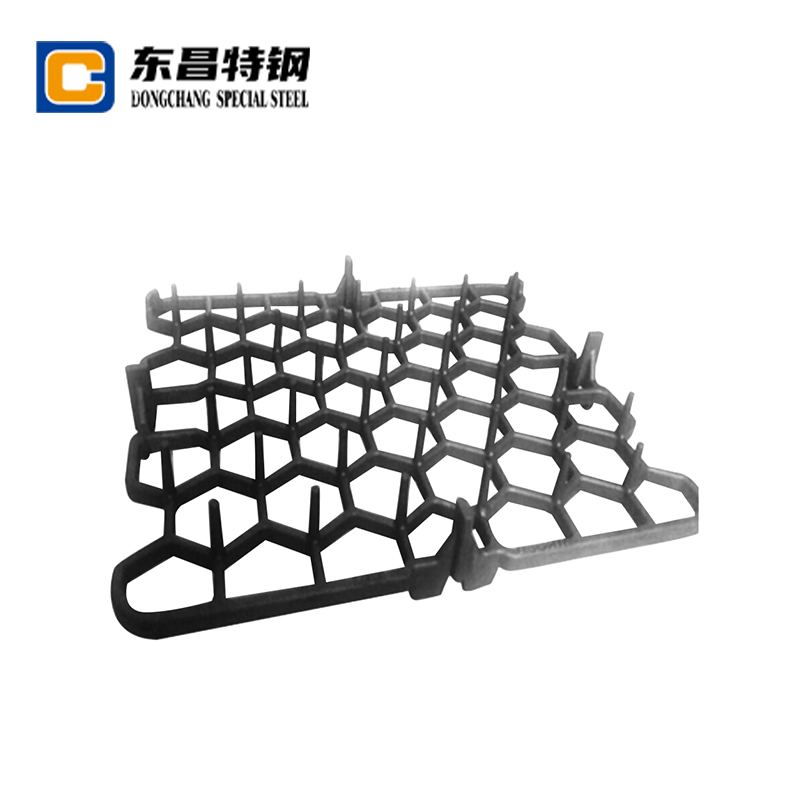

These castings are precision-engineered metal parts used to replace or repair components in industrial furnaces. Common examples include:

Burner nozzles

Heat exchanger tubes

Grate bars

Thermocouple protection tubes

Door frames and hinges

They are typically made from heat-resistant alloys such as stainless steel, cast iron, or nickel-based superalloys.

Key Benefits of High-Quality Furnace Castings

Extended Equipment Lifespan – Precision-cast parts reduce wear and tear on furnace systems.

Improved Thermal Efficiency – Properly fitted components maintain optimal heat transfer.

Reduced Downtime – Durable castings minimize frequent replacements.

Customization Options – Parts can be tailored to specific furnace designs.

Cost Savings – Long-lasting castings lower maintenance expenses over time.

Common Applications Across Industries

Steel Industry – Used in blast furnaces, reheating furnaces, and annealing lines.

Glass Manufacturing – Essential for melting furnaces and forming equipment.

Chemical Plants – Resistant to corrosive atmospheres in reaction chambers.

Power Generation – Critical for boiler components in thermal power stations.

Material Comparison for Furnace Castings

| Property | Stainless Steel Castings | High-Nickel Alloys | Cast Iron | Ceramic-Reinforced |

|---|---|---|---|---|

| Max Temperature Resistance | 1000°C - 1100°C | 1200°C - 1300°C | 700°C - 800°C | 1500°C+ |

| Corrosion Resistance | High | Very High | Moderate | Extreme |

| Mechanical Strength | Good | Excellent | Fair | Brittle |

| Typical Cost | Moderate | High | Low | Very High |

Selecting the Right Casting Supplier

When sourcing industrial furnace castings, consider:

Material Certification – Ensure compliance with ASTM/EN standards.

Manufacturing Capabilities – Look for sand casting or investment casting expertise.

Lead Time – Suppliers with ready patterns reduce delivery times.

After-Sales Support – Technical assistance for installation and maintenance.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878